1. Core Definition and Function

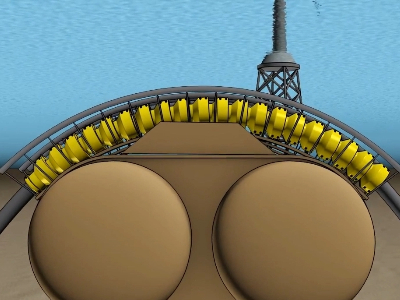

A centralizer is a critical downhole tool in cementing operations, whose core function is to ensure the casing maintains centralization within the borehole. In marine engineering, especially in highly deviated wells, horizontal wells, and deepwater drilling, the role of the centralizer becomes even more crucial due to the significant eccentricity effect caused by the weight of the casing string and complex wellbore trajectories.

Primary Functions:

Ensuring Cementing Quality: Improves casing centralization, resulting in a uniform thickness of the cement sheath in the annulus between the casing and borehole wall, effectively preventing cement channeling and ensuring zonal isolation.

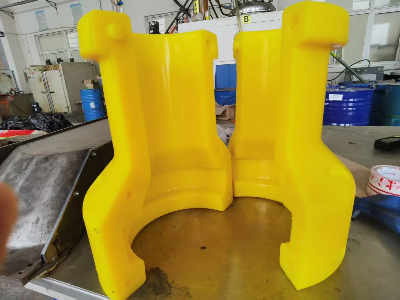

Reducing Running Friction: Optimally designed centralizers can reduce friction and sticking risks during casing running operations.

Protecting Casing Coating: Prevents direct contact between the casing body and the borehole wall, mitigating damage to the anti-corrosion coating.

2. Special Challenges and Higher Requirements in Marine Environments

Marine engineering imposes performance requirements on centralizers that far exceed those for land applications:

Extremely High Centralization Requirements: Marine oil and gas wells involve high costs and immense risks, demanding extremely stringent cementing quality. Typically, centralization exceeding 90% is required for the entire well section, especially critical zones, to ensure well integrity over its intended lifespan, which can span decades.

Harsh Mechanical Environment: Dynamic loads from waves and currents cause platform motion, transmitted downhole via the drilling riser, challenging the strength and fatigue life of centralizers and the casing string.

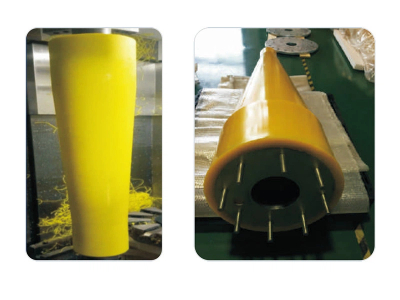

Severe Corrosive Environment: Exposure to seawater, humid atmosphere, and acidic media like hydrogen sulfide/carbon dioxide in formations requires centralizer materials to possess excellent corrosion resistance. Materials often include duplex stainless steel, super duplex stainless steel, or high-performance anti-corrosion coatings.

Complex Wellbore Trajectories: Marine drilling commonly employs extended-reach wells and horizontal wells drilled from a single platform. Centralizers must provide sufficient restoring force in large-dogleg sections while maintaining good pass-through capability.

3. Main Types and Selection Considerations

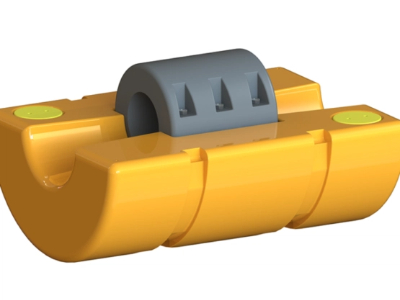

Solid Rigid Centralizers: Manufactured from solid metal, they provide the highest restoring force but lack elastic deformation capability. Typically used in vertical sections or as starter centralizers.

Bow-Spring Centralizers: Constructed from spring steel strips, they offer good elastic deformation capability, allowing them to pass through restricted borehole sections. They are the most common and economical type, but their restoring force and recentering capability are influenced by borehole diameter.

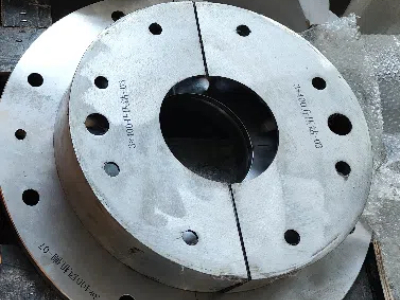

Solid Slip On Spiral Blade Casing Centraliser: Feature helically arranged blades. Their advantage lies in providing effective centralization while significantly improving the flow field of drilling fluid or cement slurry, reducing turbulence, and enhancing displacement efficiency. Additionally, their spiral structure results in lower running friction, making them preferred for marine extended-reach wells.

4. Key Selection Parameters:

Restoring Force: The centralizer's ability to return to its original diameter; a core indicator of its centralization effectiveness.

Maximum Outer Diameter & Closed Diameter: Relates to its ability to pass through complex sections like borehole doglegs.

Material Grade & Corrosion Resistance: Must be selected based on the downhole chemical environment.

Conclusion:

In the high-technology, high-risk field of marine engineering, the centralizer has evolved from a simple "spacer" into a precision engineering system affecting well integrity and long-term production safety. Its correct selection and proper placement design are foundational to the successful construction of marine oil and gas wells.

For detailed technical support or application-specific recommendations, please contact our engineering team.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.