In the field of marine engineering, bend limiters can prevent bending fatigue, tensile stress, impact damage and other problems that occur when cables and umbilical cables are running underwater for a long time. They are key protective devices for the safe operation of submarine cables. Philson polyurethane offshore cable bend limiters are widely used in offshore wind power, oil platforms, floating structures and other engineering projects with their reasonable structural design and high-performance materials.

Structural composition of offshore cable bend limiters

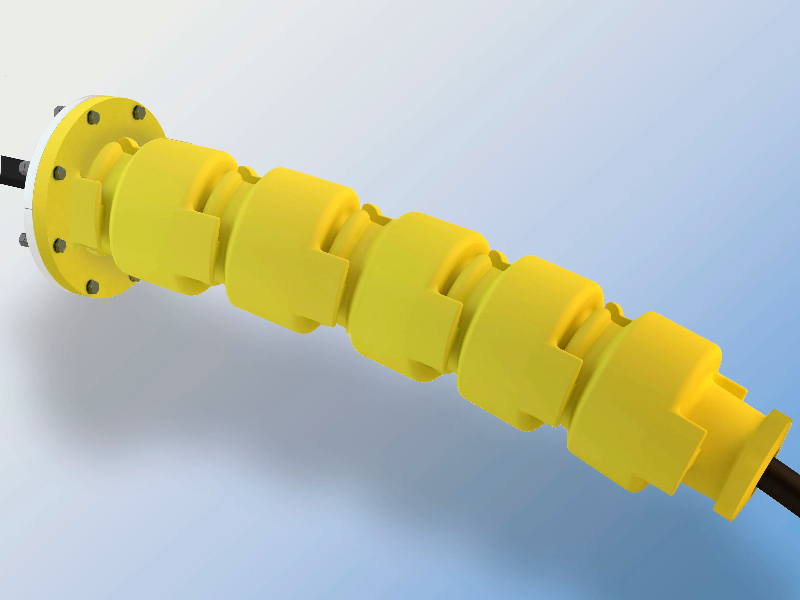

Polyurethane bend limiters usually adopt a modular sleeve structure, which consists of multiple interlocking units connected by pins and arranged around cables or umbilical cables to form protection.

Polyurethane shell

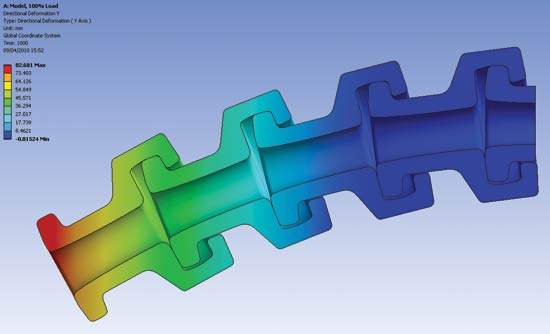

Each section of the structure is molded with high-strength cast polyurethane and is semi-cylindrical. Two symmetrical shells form a complete tubular module. The geometric structure of each module is accurately calculated to form a gradually increasing bending radius, thereby preventing the cable bending radius from being too small.

Inner channel structure

The inner cavity is precisely designed according to the target cable diameter to ensure that the cable fits without applying additional pressure.

Connection structure (pin + limit structure)

The modules are locked sequentially through high-strength metal pins to form a continuous structure with flexible and variable but limited angles.

Installation accessories (support frame/clamp ring/fastener)

Used to be installed on structures such as J-tube, I-tube, PLET or cable transition points.

Performance advantages of polyurethane materials

Philson bending limiter uses marine-grade polyether polyurethane material, which has the following significant advantages:

• High strength and high resilience: Can withstand continuous wave impact and tensile deformation.

• Resistant to seawater corrosion: No expansion or degradation after long-term immersion in seawater.

• Anti-ultraviolet and aging: Adapt to long-term environmental exposure on the sea surface/underwater.

• Strong temperature adaptability: Suitable for a wide temperature difference environment from -40℃ to +80℃.

• Self-lubricating and low wear: Does not damage the cable sheath, effectively extending the cable life.

Typical application scenarios of submarine cable protection accessories

Offshore wind farm cable protection

The cable is susceptible to bending fatigue caused by waves when passing from the wind turbine tower to the J-tube, and a bend limiter is required to protect the cable transition section.

Floating platform (FPSO) umbilical cable system

At the connection between the riser or umbilical cable and the underwater base, in order to reduce the stress impact of the sea current and hull movement on the cable.

Underwater cable landing section protection

The cable landing point or the seabed to the platform section is prone to sharp bends, and a bend limiter is required to make a smooth transition to prevent sharp bends.

ROV control cable or optical cable protection

Precision equipment control lines are equipped with limiters in the bend radius sensitive area to improve overall stability and durability.

Polyurethane offshore cable bend limiters effectively control the cable bending radius and prevent fatigue damage through modular structural design and engineering-grade material selection. They are key components to ensure the reliable operation of submarine cables and umbilical cables. Philson provides a variety of specifications and customized solutions to adapt to different cable diameters, cable paths and installation structures. Please contact us for professional selection suggestions.