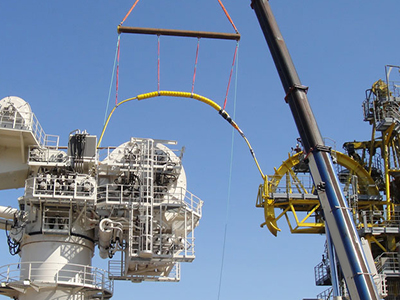

The submarine umbilical polyurethane vertebral bend restrictor is a key protection device used in underwater engineering or marine equipment. It is mainly used to protect flexible pipelines (such as submarine cables, umbilical cables, etc.) from excessive bending or mechanical damage in the marine environment. The following is a detailed analysis of the two aspects of design features and functions:

Vertebrae bending restrictor design features

• Material selection: polyurethane (PU)

High elasticity and wear resistance: polyurethane has both the elasticity of rubber and the rigidity of plastic, and can withstand repeated bending and dynamic loads.

Corrosion resistance: Resistant to erosion by seawater, salt spray, and chemical media, suitable for long-term underwater operations. Polyurethane materials can be used for at least 25 years.

Low water absorption: Reduce material performance degradation caused by water absorption.

• Bionic vertebral structure design

Segmented module: A segmented structure similar to the spine, each segment is independent but interconnected, allowing a limited angle of bending.

Limiting slot or flange: A physical limiting structure (such as protrusions and grooves) is set between adjacent vertebrae to limit the bending angle through mechanical interference.

Articulated connection: adopts axle pin or flexible joint design to ensure flexibility and anti-torsion ability.

• Dynamic environmental adaptability

Compression and tension design: reinforcement layers (such as fiber braid or metal ring) can be embedded inside as needed to resist deep-sea high pressure and water flow impact.

Buoyancy adjustment: balance the weight distribution of the equipment in the water by adjusting the material density or adding buoyancy modules.

• Integration and modularization

Customizable length: flexibly assemble vertebral modules according to the length and bending requirements of the umbilical cable.

Quick installation interface: design snap or bolt connection for easy installation or replacement.

• Sealing and protection

Waterproof sealing ring: set a sealing structure at the vertebral connection to prevent mud or biological intrusion.

Anti-biological adhesion coating: surface treatment reduces the adhesion of marine organisms and reduces maintenance frequency.

The core role of the submarine bending limiter

• Mechanical protection

Limit the bending radius: prevent the internal optical fiber, cable, or hydraulic pipe from breaking due to excessive bending of the umbilical cable.

Disperse stress: Disperse external loads (such as water flow impact, equipment drag) through segmented structures to reduce local stress concentration.

• Extend service life

Reduce fatigue damage: Suppress material fatigue caused by repeated bending in dynamic environments.

Anti-wear protection: The polyurethane shell can resist physical damage caused by friction with seabed rocks and equipment.

• Environmental adaptability

Deal with complex terrain: Ensure that the umbilical cable operates within a safe bending range when on rugged seabed or close to drilling platforms.

Adapt to temperature changes: Polyurethane can still maintain elasticity at low temperatures (deep sea waters) to avoid embrittlement.

• Improve system reliability

Reduce failure rate: Reduce the risk of accidental bending through mechanical limiters to ensure the continuity of power, signal, or fluid transmission.

Compatible with multiple application scenarios: Suitable for oil and gas exploration, seabed observation networks, underwater robots, and other scenarios.

Philson cable bend protection accessories have been recognized by customers in the oil and gas offshore industry and renewable energy fields. If you have special application requirements for submarine cable protection systems, you can contact us at any time. We can provide you with cost-effective solutions through optimized design methods, continuous development programs, and the use of a wide range of rigid PU grades.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.