Distributed buoyancy modules (DBMs) play a crucial auxiliary role in the layout and protection of flexible cables in offshore wind farms, as well as in fixing and lifting submarine cables, thereby effectively ensuring the stable operation and long-term reliability of wind power systems.

Material characteristics

Distributed buoyancy modules usually use high-performance materials with good compression resistance, corrosion resistance, and long life:

Closed-cell polyurethane foam (PU Foam): core floating body material, adjustable density, closed-cell structure to ensure long-term buoyancy stability, and high compressive strength.

Composite shell structure: The exterior is usually a high-strength polymer or epoxy fiberglass shell, which is impact-resistant and seawater-resistant.

Lining elastic protective layer: The contact part between the module and the cable uses rubber or polyurethane lining to effectively avoid wear and pressure on the cable sheath.

Structural design

The distributed buoyancy module adopts a clip-on or bolt-on structure, which is easy to install and maintain. The overall design is modular, which is convenient for transportation and segmented deployment:

Semi-circular arc module buckle structure: It consists of two parts, upper and lower, wrapped around the outside of the cable, and fixed by fasteners, suitable for cables of different diameters.

Multi-segment buoyancy distribution system: The buoyancy can be distributed along the cable in segments as required, which is used to build a specific catenary shape (such as a Lazy Wave configuration).

Integrated anti-slip grooves and drainage channels: Improve the stability of the module, prevent displacement, and help quickly exhaust during underwater deployment.

Application location and scenario

In offshore wind power projects, distributed buoyancy modules are mainly used in the following key locations:

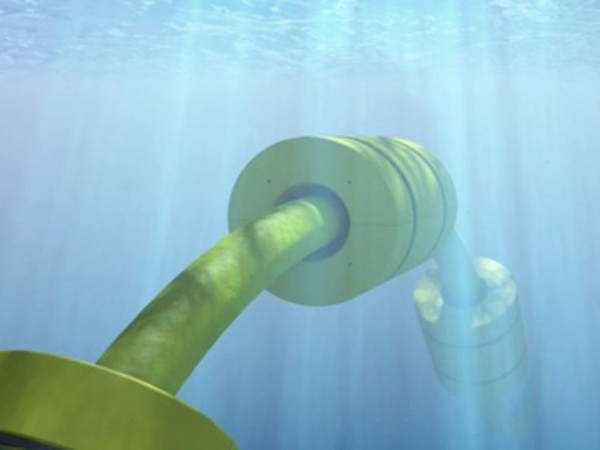

• Export cable catenary section (Dynamic cable section)

It is used to connect the submarine cable with the floating wind power platform, floating substation, or floating foundation, and the buoyancy control cable forms an ideal "S" or "crescent" shape to reduce the impact of dynamic loads.

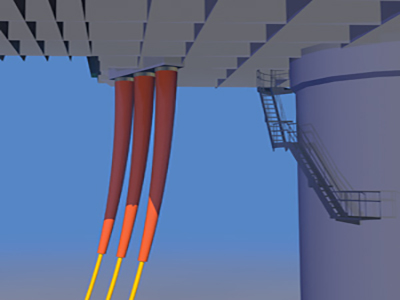

• The interface between the wind turbine and the submarine pipeline

Under the wind turbine tower, distributed buoyancy is used to adjust the direction and shape of the cable, and alleviate the stretching and bending of the cable caused by the movement of the turbine.

• The connection section between the floating substation and the submarine cable

The floating substation in the wind farm needs to be flexibly connected to the submarine collector cable. DBM can effectively adjust the cable shape and reduce the bending radius and fatigue stress.

• Cable laying system in a deep-water wind farm area

In a deep-water (>50m) operating environment, the cable needs to cross the complex seabed topography. The distributed buoyancy module helps the cable form a transition section away from the bottom to prevent dragging and wear.

Dynamic buoys play an indispensable role in offshore wind power cable laying projects. Its excellent buoyancy performance, reliable structural design, and high adaptability ensure the safety and durability of wind power cable systems in complex sea conditions. With the development of deep-sea wind power technology, the application of DBM will be more extensive, helping to safely and efficiently transport green energy to land.