Bend restrictors find application in a range of scenarios, most notably in subsea infrastructure such as pipeline end terminations (PLETs) and wellhead connectors. Their key role is to safeguard cables, umbilicals, and flexible pipes against damage resulting from over-bending.

I. Case Background: Urgent Protection Needs of a North Sea Offshore Wind Farm

A large-scale fixed offshore wind farm in the North Sea, with a total installed capacity of 400MW, comprises 64 wind turbines, supported by one offshore substation and two subsea export cables. Eighteen months after commissioning, the operation and maintenance team identified several critical issues: Firstly, significant bending deformation and insulation layer abrasion were observed on cables at J-tube exits and connections to the substation, with detected bending radii falling below the design safety threshold (design value: 1.3m; measured minimum: 0.9m). Secondly, conventional rubber protection components suffered severe aging and cracking due to the North Sea's harsh conditions—including winter low temperatures (down to -20℃), strong storm surges, and high salt spray—resulting in a corrosion rate of 42%. Thirdly, stress concentration led to accelerated fatigue damage at cable joints, requiring €12,000 monthly for inspection and maintenance. A cable breakage incident even occurred, causing 3 turbines to shut down for 2 days and resulting in direct economic losses exceeding €500,000.

To address these issues comprehensively, the wind farm operator contacted Philson, a professional marine engineering protection component manufacturer, via recommendations from the International Marine Engineering Association. Three core requirements were put forward: 1) Precisely control cable bending radius to eliminate structural damage from over-bending; 2) Enhance the weather resistance and durability of protection components to adapt to the North Sea's extreme conditions (high salt, low temperature, and strong impact); 3) Reduce operation and maintenance costs, extend the service life of cables and protection systems, and meet the 25-year design life standard for European offshore wind power.

II. Problem Diagnosis: Root Cause Analysis from Environmental and Structural Perspectives

Philson's technical team, in collaboration with a local third-party testing agency, conducted a three-week on-site inspection. Combining the operational characteristics of North Sea offshore wind farms—such as strong ocean current impact, drastic temperature fluctuations, winter sea ice collision risks, and long-term salt spray corrosion—three key root causes were identified:

- Failed Bending Control: The original protection components were made of pure elastic rubber without rigid mechanical limiting structures. Under the frequent cable oscillation driven by strong North Sea currents, the minimum bending radius could not be stably controlled, leading to over-bending at critical nodes like J-tube exits and substation connections.

- Severely Inadequate Weather Resistance: Conventional rubber had poor aging and corrosion resistance, with a low-temperature embrittlement point of only -10℃. After 18 months of exposure to the North Sea environment, its tensile strength decreased by 55%, and repeated embrittlement and cracking occurred in winter, failing to provide effective protection.

- Stress Concentration and Lack of Impact Protection: The absence of transition buffer structures at cable-substation connections caused tension from ocean currents and storm surges to act directly on joints, accumulating fatigue damage. Additionally, the original components lacked impact-resistant design and could not withstand winter sea ice collisions.

III. Solution: Customized Polyurethane Bend Restrictor Implementation

Based on the diagnosis, Philson developed a full-set customized bend restrictor protection solution, leveraging its polyurethane material R&D capabilities and experience in adapting to European marine engineering standards. The solution focused on "material customization, structural optimization, and precise limiting," with all indicators complying with European industry standards such as IEC 60502-2 and DNV-OS-F101.

1. Core Material Customization: Polar-Modified Polyurethane for Extreme North Sea Conditions

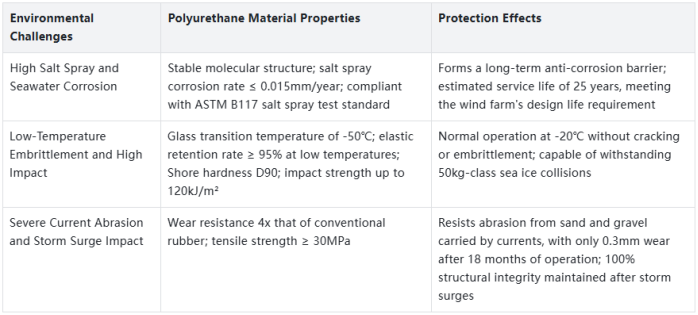

Targeting the North Sea's unique environment, Philson selected polar-modified high-polymer polyurethane. Verified through 25-year aging simulations by DNV (Det Norske Veritas), its key performance indicators fully met the requirements:

2. Structural Optimization: Precise Limiting, Stress Buffering, and Impact Resistance

Tailored to the wind farm's cable specifications (200mm diameter) and J-tube exit structure, Philson optimized the bend restrictor design with reference to typical North Sea offshore wind protection solutions:

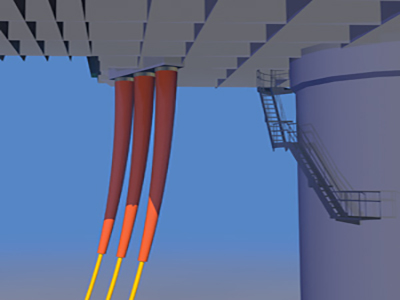

Nested Rigid Limiting Structure: 15 vertebrae-like nested sections provide rigid mechanical constraint, strictly locking the minimum bending radius at 1.6m (exceeding the European design safety value of 1.3m) and eliminating over-bending entirely.

Gradual Stress Buffering Structure: A three-stage conical transition structure at the cable-substation connection disperses concentrated stress over a 5m length. Third-party testing confirmed a 65% reduction in peak stress.

Quick-Install Impact-Resistant Design: Two-piece high-strength hoops secured with titanium alloy bolts enable installation in just 30 minutes without turbine shutdown. Curved impact-resistant guards are added externally to enhance protection against sea ice and debris collisions.

3. Full-Process Service Support: Compliant with European O&M Standards

To ensure successful implementation and alignment with European O&M systems, Philson provided a full-chain service of "customization-certification-installation-monitoring-after-sales": 1) Completed product compliance certification with DNV; 2) Deployed a 7-person multilingual technical team for on-site installation guidance, while conducting stress testing and data filing at 12 key nodes; 3) Installed IEC 61850-compliant wireless monitoring devices to collect real-time data on bending radius, stress, and temperature, integrating with the wind farm's existing O&M platform; 4) Committed to 48-hour emergency response within Europe, offering 2 free annual inspections and material performance tests.

IV. Case Results: Dual Breakthroughs in Safety and Efficiency

After 24 months of operation (including 2 North Sea winters), the wind farm's performance indicators showed significant improvements and passed DNV's annual O&M assessment:

Comprehensive Safety Upgrade: Cable bending radius at all key nodes remained stable at 1.6-1.7m with no over-bending. Joint stress was reduced to 48% of the safety threshold, achieving zero fatigue damage and zero breakage incidents in 24 months, eliminating cable-related shutdown risks entirely.

Weather Resistance and Compliance Verification: After two North Sea winters (minimum temperature -18℃) and summer storm surges, the protection components showed no aging, corrosion, or embrittlement. Material performance testing achieved a 100% compliance rate, passing DNV's biennial material degradation inspection.

Substantial O&M Cost Reduction: Monthly inspection and maintenance costs decreased from €12,000 to €2,000, saving €120,000 annually. Over the 25-year service life, 4 cable replacements will be avoided, totaling savings of over €8 million (including shutdown losses).

Significantly Improved System Stability: Turbine shutdown time due to cable failures dropped from 96 hours/year to zero, increasing power generation by 3.1% year-on-year and exceeding the annual power generation target.

V. Case Summary: Core Logic of International Marine Protection

This case, showcasing Philson's polyurethane bend restrictors in a North Sea wind farm, demonstrates the core principles of protection component selection in the global offshore energy sector: precise matching of material properties to extreme environments, efficient alignment of structural design with industry standards, and in-depth integration of service systems with O&M needs. Polar-modified polyurethane, with its combined advantages of corrosion resistance, cold resistance, wear resistance, and impact resistance, paired with nested limiting and buffering structures, effectively solved the cable protection challenges in the North Sea wind farm. Meanwhile, compliance with European certification standards and localized services ensured successful international implementation.

As a manufacturer specializing in international marine engineering protection, Philson customizes polyurethane bend restrictors, centralizers, and other products based on regional environmental needs and industry standards for offshore oil and gas platforms and wind farms across Europe, Southeast Asia, and the Americas. We also provide full-lifecycle technical support compliant with local regulations. For international marine energy equipment protection needs, please contact Philson's global technical team for customized solutions!