Polyurethane sheets (PU sheets) have become one of the most essential materials in industrial manufacturing, engineering, and mechanical design. Combining the elasticity of rubber, the toughness of metal, and the versatility of plastic, polyurethane sheets deliver a unique balance of strength, flexibility, and durability that few materials can match.

As a trusted polyurethane sheet manufacturer, we supply custom polyurethane sheets designed to perform under the most demanding conditions — from heavy load-bearing environments to precise sealing and vibration control.

1. Exceptional Material Properties

The performance of a polyurethane sheet comes from its highly customizable mechanical characteristics. By adjusting its formula, the sheet can offer different levels of:

Hardness — from soft (Shore A 20) to rigid (Shore D 70)

Rebound energy — for applications needing impact absorption or elasticity

Compression resistance — ensuring long-term dimensional stability under pressure

Abrasion and wear resistance — providing long service life in harsh conditions

These properties make polyurethane sheets ideal for use in both dynamic and static applications.

2. Key Advantages of Polyurethane Sheets

Polyurethane sheets offer several significant advantages over traditional rubber, plastic, or metal materials:

Superior wear and abrasion resistance

Excellent load-bearing and impact performance

Oil, chemical, and solvent resistance

Outstanding flexibility and vibration damping

Easy to machine, cut, or mold into custom shapes

Because of these combined benefits, polyurethane has become the preferred choice for industrial protection and support systems.

3. Diverse Industrial Applications

Polyurethane sheets are widely used across various industries due to their versatility and strength:

▪ Material Handling:Used as liners, rollers, bumpers, and impact pads on conveyor systems to absorb shocks and prevent damage.

▪ Automotive and Transportation:Applied in suspension systems, gaskets, and noise-reduction pads for enhanced comfort and durability.

▪ Industrial Machinery:Used as wear plates, scrapers, seals, and vibration isolators in heavy-duty equipment.

▪ Construction and Engineering:Ideal for shock absorption, load support, and sealing in foundation and building structures.

▪ Mining and Energy:Employed in chutes, hoppers, and screen panels due to excellent wear and tear resistance.

4. Customization for Specific Needs

One of the biggest strengths of polyurethane sheets is customization.

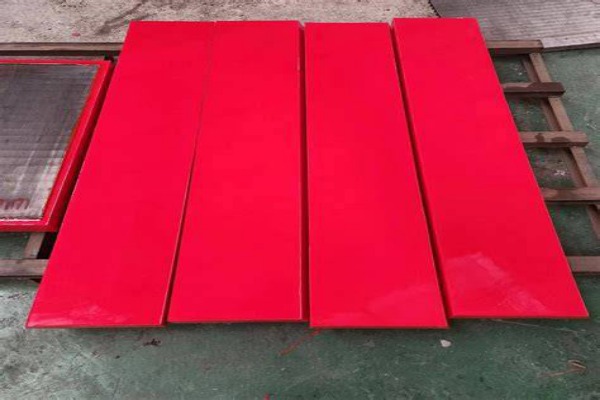

Manufacturers can tailor sheet thickness, hardness, color, and mechanical performance to match specific requirements. Whether you need a soft cushioning PU sheet or a hard structural polyurethane board, the formulation can be precisely adjusted for optimal performance.

5. A Reliable Choice for Long-Term Value

In industrial applications where strength, durability, and flexibility are crucial, polyurethane sheets consistently outperform traditional materials. They extend the lifespan of machinery, improve safety, and reduce maintenance costs — providing a cost-effective solution for modern engineering challenges.

Conclusion

Polyurethane sheets are the perfect combination of performance, adaptability, and reliability. With their diverse applications and outstanding mechanical properties, PU sheets have become a key material in modern industry. If you’re looking for custom polyurethane sheets that meet your exact performance needs, contact us — your trusted polyurethane sheet manufacturer — for professional solutions and expert support.