As a polymer formed through the chemical reaction of polyols and isocyanates, Polyurethane (PU) Blocks have become an indispensable raw material in numerous fields, ranging from architectural insulation to precision machining.

I. Material Characteristics: Why Choose Polyurethane?

Extensive Hardness Range: By adjusting the chemical formulation, polyurethane can range from sponge-like softness (Shore A scale) to the extreme hardness of nylon or metal (Shore D scale).

Superior Wear Resistance: Its abrasion resistance is typically several times that of natural rubber, making it an ideal choice for high-friction environments.

Energy Absorption and Damping: It possesses excellent vibration damping properties, allowing it to effectively absorb impact forces and quickly return to its original shape.

Environmental Resistance: It offers outstanding resistance to oils, chemicals, and ozone, while maintaining stability under extreme high and low temperatures.

II. Diverse Manufacturing Processes

Different manufacturing methods are employed based on specific application requirements:

Reaction Injection Molding (RIM): Raw materials are injected directly into a mold. This is suitable for manufacturing parts with complex shapes and high consistency.

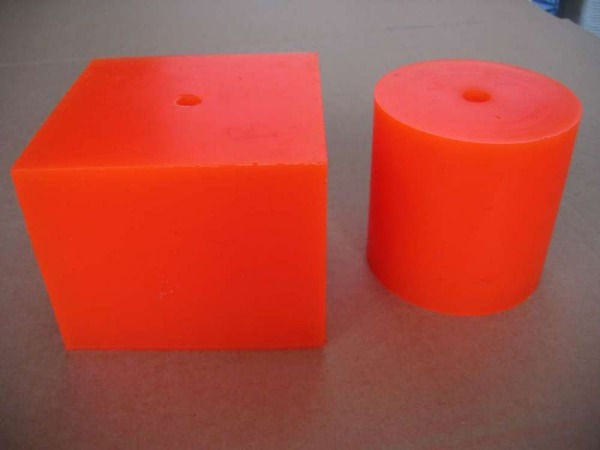

Open Casting: This is the most common process, used to produce large-sized square, rectangular, or round base blocks, which are convenient for subsequent mechanical processing.

Slabstock Foaming: Raw materials foam and solidify while in motion, forming giant blocks up to dozens of meters long, which are then cut into standard sizes.

III. Wide Range of Applications

Since polyurethane blocks can be CNC machined (turning, milling, planing, drilling) much like wood or metal, their applications cover almost all industrial sectors:

Mechanical Prototypes and Molds: High-hardness PU blocks are frequently used to machine industrial prototypes because they are lighter than metal and offer lower processing costs.

Automotive Industry: Utilizing its damping properties, it is used to manufacture bushings, internal bumper buffers, and vehicle Noise, Vibration, and Harshness (NVH) components.

Packaging Protection: Custom-cut soft or semi-rigid blocks provide armor-grade logistics protection for precision electronic instruments.

Construction Engineering: Used as structural insulation blocks to solve thermal bridge issues in cold storage or energy-efficient buildings, significantly enhancing energy efficiency.

IV. Conclusion

With its core advantage of customizability, polyurethane blocks bridge the gap between traditional materials in terms of toughness, wear resistance, and ease of processing. With the integration of eco-friendly technologies such as bio-based materials, polyurethane blocks will play an even more critical role in sustainable industrial development in the future.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.