In the demanding environment of offshore wind power, Bend Restrictors (BRs) are indispensable components. They safeguard subsea export and array cables by preventing overbending and mechanical degradation, effectively mitigating corrosion risks and significantly extending the infrastructure's operational lifecycle.

What is an Offshore Bend Restrictor?

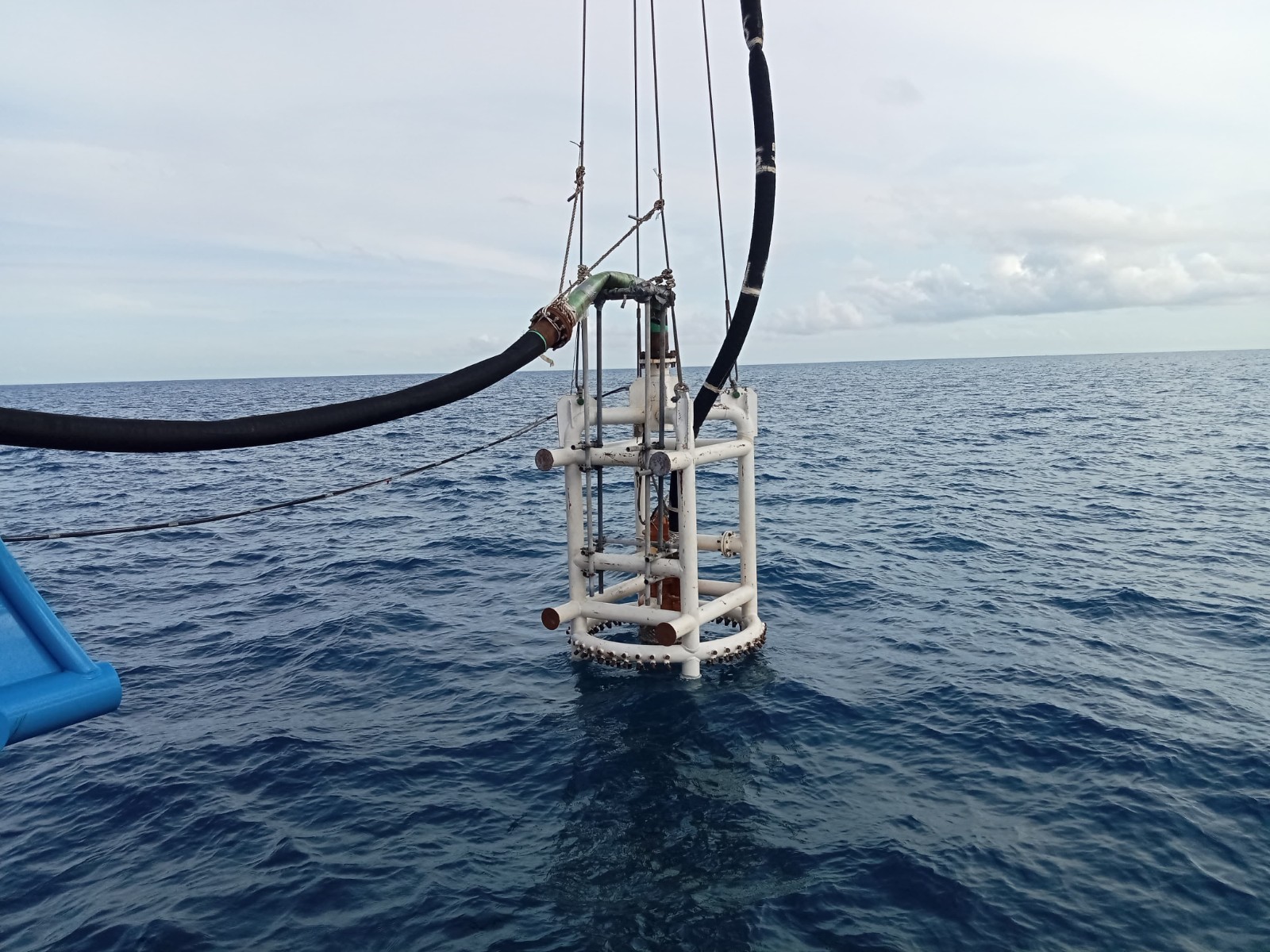

An offshore bend restrictor is a high-engineered mechanical protection system, typically comprising interlocking segments of high-grade polyurethane (PU) or advanced composites. It is specifically designed to limit the bending of flexible subsea cables or umbilicals to a pre-determined Minimum Bend Radius (MBR).

By providing a rigid mechanical stop, these "vertebrae" systems ensure that cables are never subjected to stresses beyond their structural limits. Typically deployed at high-stress interfaces—such as J-tube exits, hang-off points, and seabed touchdown zones (TDZ)—bend restrictors act as the primary defense mechanism in a comprehensive Subsea Cable Protection System (CPS).

Engineering Synergy: How Bend Restrictor Prevent Cable Corrosion

While primarily mechanical, bend restrictors provide a critical indirect barrier against corrosion by maintaining the cable's structural sealing.

Preservation of Sheath Integrity Excessive bending during installation or dynamic operation can induce micro-cracks in the cable's outer polymer sheath. Any breach leads to seawater ingress, triggering rapid galvanic corrosion of the armor wires and copper conductors. By enforcing MBR compliance, bend restrictors prevent sheath compromising, ensuring a watertight barrier against the saline environment.

Mitigation of Dynamic Fatigue Offshore wind cables endure constant cyclic loading from tidal currents and wave action. This leads to bend fatigue, which can degrade metallic shielding over time. Bend restrictors redistribute these hydrodynamic forces across a controlled arc, minimizing localized strain and preventing fatigue-induced fractures that would otherwise expose internal components to seawater.

Interface Stress Shielding Stress concentration is highest at rigid-to-flexible transition points (e.g., J-tube). Bend restrictors shield these vulnerable interfaces, preventing mechanical abrasion and ensuring that the cable's water-blocking layers remain intact under extreme environmental loads.

Technical Advantages of Polyurethane (PU) Bend Restrictors

Inherent Chemical Stability: Marine-grade polyurethane is naturally immune to saltwater corrosion, UV degradation, and biofouling (marine growth), ensuring performance stability for decades.

Extended Design Life: Engineered for a service life of 25+ years, our restrictors are designed to match or exceed the operational lifespan of the offshore wind farm itself.

Modular Precision: The interlocking "vertebrae" geometry allows for fluid movement within safe tolerances while providing an absolute lock-out to prevent kinking.

OPEX Efficiency: As a passive protection system, PU bend restrictors are virtually maintenance-free, significantly reducing long-term Operations & Maintenance (O&M) costs for developers.

Conclusion

Bend restrictors are far more than mere mechanical sleeves; they are a strategic investment in Subsea Asset Integrity. By neutralizing mechanical fatigue and preserving the cable’s primary sealing layers, they eliminate the root causes of subsea corrosion. For offshore wind operators, this translates to reliable power transmission, reduced intervention costs, and a maximized Return on Investment (ROI).