Polyurethane bend restrictors protect subsea oil and gas flowlines from overbending, ensuring long-term durability, corrosion resistance, and a service life of over 25 years in harsh offshore environments.

What is a flowline, and where is it used?

A flowline is a pipeline that transports crude oil, gas, or a multiphase mixture (oil, gas, water) from one point to another within a subsea production system. Typically, it connects the Christmas tree or subsea wellhead to a manifold, or routes fluids directly to a riser base that leads to the topside platform. Flowlines are often laid directly on the seabed or supported by subsea structures, exposed to environmental loads such as current, wave-induced motion, or platform movement.

Because these pipelines are subjected to constant dynamic loading, bending, and tension, particularly near connection points (e.g., at hang-off points or touchdown areas), they require mechanical protection to prevent excessive bending, which can lead to fatigue failure or even rupture. This is where the flowline bend restrictor becomes essential.

Why install a bend restrictor on a subsea flowline?

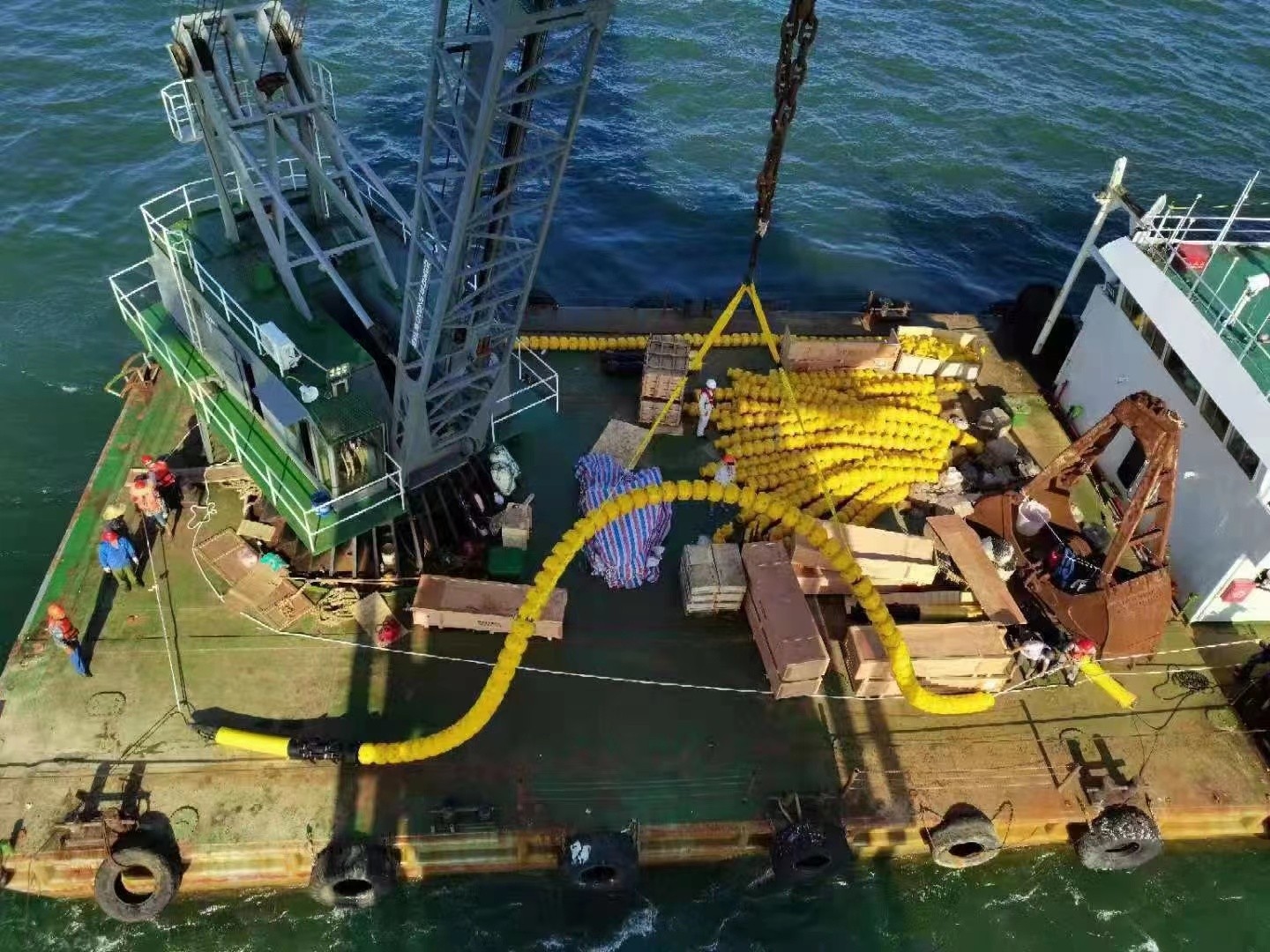

A bend restrictor is designed to limit the bending radius of a flexible pipeline to a predefined minimum value. It typically consists of multiple interlocking polyurethane segments, forming a vertebra-like structure that provides flexibility within a safe range while mechanically blocking overbending beyond that range.

Key areas where bend restrictors are commonly installed on flowlines include:

• At the interface between the flowline and the rigid structure (e.g., plem, riser base, or manifold)

• Near hang-off points on platforms or FPSOs

• At the flowline touchdown point on the seabed

• Anywhere that cyclic motion or hydrodynamic forces induce bending stress

Without proper bend restriction, the flexible flowline can bend beyond its critical radius, leading to kinking, fatigue damage, internal layer separation, or failure of the flowline armor layers.

Advantages of polyurethane bend restrictors

Among various materials used for bend restrictors, polyurethane stands out due to its excellent mechanical and environmental properties. The key advantages of using polyurethane bend restrictors for flowline protection include:

• Superior corrosion resistance

Unlike metallic components, polyurethane is inherently resistant to seawater corrosion, marine biofouling, and chemical degradation. It performs reliably in harsh subsea environments for long durations without requiring coatings or sacrificial protection systems.

• Long service life (25+ years)

Polyurethane bend restrictors are engineered for long-term subsea deployment, with a typical design life exceeding 25 years. This longevity reduces maintenance intervals and total lifecycle costs, aligning with the operational expectations of modern subsea production fields.

• Controlled bending range

The interlocking vertebra structure is precisely designed to allow controlled bending within a safe range, absorbing movement from waves, currents, and equipment operations. Once the bend angle exceeds the critical value, the restrictor locks up and prevents further motion, protecting the flowline from structural damage.

• Mechanical strength and flexibility

Polyurethane offers high impact resistance, flexibility, and dimensional stability, even under cyclic loading. It can handle high compressive and shear stresses, making it ideal for deepwater applications where pressure and movement coexist.

• Customizable and easy to install

Polyurethane bend restrictors can be tailored to specific flowline diameters, bending radii, and loading conditions. Their modular segment design allows for quick installation offshore, minimizing vessel time and deployment complexity.

The flowline bend restrictor is a vital component in subsea oil and gas systems, offering targeted protection at mechanical stress points and ensuring the structural integrity and safe operation of critical hydrocarbon pipelines. By choosing a polyurethane-based bend restrictor, offshore operators benefit from enhanced corrosion resistance, proven 25+ year service life, and flexible mechanical performance, making it the ideal solution for safeguarding subsea flowlines in today’s deepwater and ultra-deepwater environments.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.