In offshore oil and gas development, a cable bend restrictor (CBR) can effectively limit the bending radius of underwater cables (such as dynamic umbilical cables, power cables, fiber optic cables, etc.), ensuring that they work within a safe range, thereby extending service life and improving system reliability. Avoid excessive bending of wires under the influence of waves, ocean currents, and platform movement due to the complex marine environment, resulting in damage to the internal structure or even breakage.

Function of the cable bend restrictor

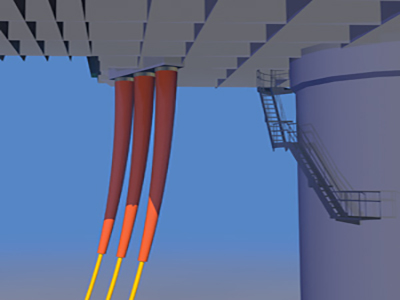

The main function of the cable bend restrictor is to limit the bending radius of the cable during installation and service to less than its minimum allowable bending radius, avoiding mechanical fatigue, sheath breakage, or internal conductor damage caused by excessive bending. CBR is widely used in submarine cables, umbilical cables, buoyancy pipelines, and various dynamic cable systems, especially in the connection area between risers, flexible pipelines, and floating platforms, playing a key protective role.

Structural features

Cable bend restrictors usually adopt a modular design and have the following structural features:

(1) Hinged articulated vertebrae (HAV)

It is composed of multiple interlocking units, similar to a "chain" structure, and can be flexibly rotated within a certain angle.

Each unit adopts a HAV (two halves) design, which is easy to assemble and maintain.

The interlocking structure ensures that the restrictor maintains integrity when bending and will not loosen due to external forces.

(2) Limited bending capacity

The restrictor allows the cable to bend freely within the designed bending radius (such as 10 to 15 times the outer diameter of the cable). If it exceeds this range, it will automatically lock to prevent further deformation.

Suitable for dynamic and static applications, such as periodic movement caused by waves or temporary bending caused by ship drift.

(3) Polyurethane material (hardness 80- 85D)

It uses high-hardness polyurethane (PU) material (Shore hardness 80- 85D), which has the characteristics of wear resistance, seawater corrosion resistance, low temperature resistance, impact resistance and high mechanical strength.

Compared with metal materials, polyurethane is lighter and will not cause wear on the outer sheath of the cable.

Oil-resistant and UV-resistant, suitable for long-term underwater or offshore exposure environments.

(4)HAV structure has the following advantages

Precisely control the minimum bending radius to prevent structural damage.

Easy assembly and maintenance, and quick disassembly and replacement of modules.

High stability and mechanical strength, suitable for dynamic load scenarios.

Adapt to a variety of installation methods, and can be integrated with J-tubes, I-tubes, and anchoring devices.

Application examples

In FPSO (Floating production storage and offloading unit), subsea production systems, and riser terminal systems, CBR is often used in the transition area where the cable is connected from the seabed to the platform. It effectively prevents repeated bending of cables caused by waves, ocean currents, and platform movement, thereby greatly improving system reliability and service life.

As a key protection accessory in marine engineering, the design technology and material performance of polyurethane cable bend restrictors are being continuously optimized with the increasing number of deepwater operations. CBR with high-strength polyurethane material and Haversian structure provides more efficient and reliable cable protection solutions for offshore oil and gas projects.

If you need to customize various types of marine CBR products, please contact us for detailed information and technical support.