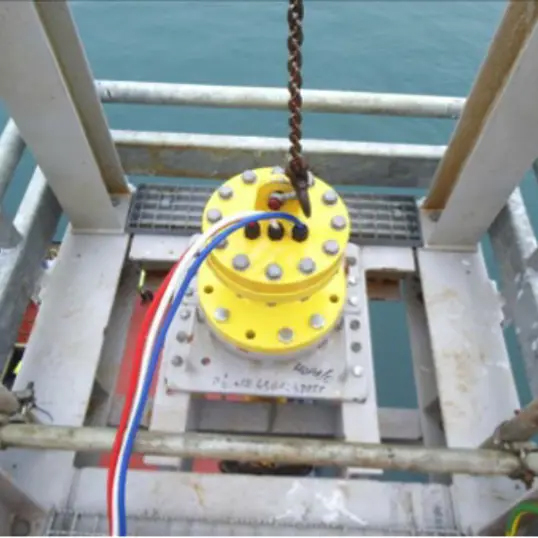

The Cable Hang-Off Clamp performs two vital functions: supporting the immense weight of the suspended subsea cable and creating a gas-tight/watertight seal to protect the internal platform environment.

1. Core Functions

The Hang-Off Clamp acts as the termination point for the mechanical loads of a subsea cable. Without it, the cable’s weight would hang directly on the sensitive electrical terminations or switchgear, leading to catastrophic failure.

Mechanical Load Transfer: It grips the cable’s armor wires (or outer sheath) and transfers the axial tension and weight of the cable directly to the foundation structure (e.g., the monopile or jacket deck). This provides essential strain relief for the inner electrical cores.

Environmental Sealing: The clamp seals the opening of the J-tube or cable deck. This prevents humidity, saltwater, and corrosive gases (like hydrogen sulphide) from entering the tower or platform, which is critical for protecting sensitive high-voltage equipment.

Vibration Damping: It limits cable movement caused by wave action and vortex-induced vibrations (VIV), reducing fatigue and chafing at the entry point.

2. Applications in Subsea & Offshore Sectors

Cable Hang-Off Clamps are standard equipment in almost every project involving subsea cabling.

Offshore Wind Farms (Fixed & Floating): Used in the transition piece of monopiles and jackets. They secure Inter-Array Cables (66kV) connecting turbines and Export Cables connecting to shore. In floating wind, they are part of the dynamic cable system, managing high dynamic loads.

Offshore Substations (OSS): Installed at the top of J-tubes where massive export cables enter the substation.

Oil & Gas Platforms: Used for Umbilicals (hydraulic/chemical injection lines) and power cables feeding subsea pumps and control modules.

3. Key Technical Features

Modern Hang-Off Clamps are engineered for a 25+ year service life in highly corrosive salt-spray zones.

Split-Body Design: Most clamps feature a split housing. This allows the clamp to be installed after the cable has been pulled through the deck, significantly reducing installation time and complexity.

Temporary vs. Permanent Locking:

Temporary Clamps: Used during the cable pull-in phase to hold the cable safely while the vessel repositions or prepares for termination.

Permanent Clamps: The final installation that locks the cable for its operational life.

Sealing Technology: Resin-Filled: The internal void is filled with a marine-grade polyurethane resin that creates a solid, void-free block, locking the armor wires in place and providing a 100% watertight seal.

Resin-Free (Mechanical): A newer technology that uses mechanical gaskets and compression to seal. This allows for faster installation and easier removal/recycling during decommissioning.

Materials: Typically manufactured from Marine Grade Stainless Steel (316L) or high-grade coated carbon steel to resist corrosion.

Conclusion

The Cable Hang-Off Clamp is a small but indispensable component of the offshore energy supply chain. Whether for securing the umbilical of an oil rig or the export cable of a gigawatt-scale wind farm, it ensures that the connection between the subsea world and the topside infrastructure remains secure, dry, and operational for decades.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.