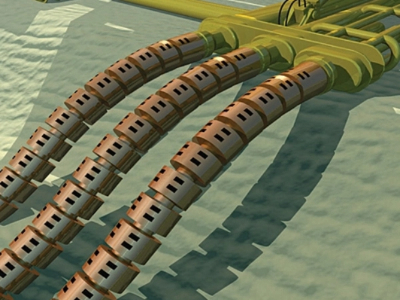

Bend fatigue protections are usually composed of a series of "vertebrae-like" joint modules made of high-strength polyurethane connected in sections. They are generally flexible and can bend slightly with the cable. Once the bending angle exceeds the designed minimum radius, these modules will abut each other to form a rigid structure, effectively preventing the cable from excessive bending. This helps:

Prevent bending-induced fatigue failure

Maintain cable structural integrity

Ensure long-term performance in harsh environments

Key characteristics

Bend restrictors are engineered with high-performance polyurethane materials and structural precision. Typical characteristics include:

Segmented vertebra design: Often constructed using interlocking polyurethane or polymer segments that mimic a vertebrae structure, allowing flexibility while enforcing a minimum bend radius.

High durability: Resistant to seawater, UV, hydrolysis, and mechanical wear.

Customizable geometry: Designed to match the cable diameter, bend radius requirements, and application environment.

Modular construction: Enables easy installation and maintenance, whether integrated during cable assembly or retrofitted offshore.

Material selection: Commonly made from reinforced polyurethane, offering high strength-to-weight ratios.

Application scenarios

Bend restrictors are indispensable in a variety of subsea and offshore installations:

Offshore wind farms: Used at the transition between dynamic and static sections of submarine power cables connected to turbines.

Oil & gas platforms: Installed at cable terminations, riser bases, or j-tube exits to prevent cable fatigue caused by wave and platform motion.

Subsea power and communication networks: Protect cables in seabed touchdown areas, cable crossings, and high-motion zones.

Floating production units (FPSO, FSRU): Deployed on dynamic umbilicals and hybrid risers to manage fatigue at top connections.

Bend restrictors are a critical element in any submarine cable protection system, effectively guarding against bending fatigue and mechanical stress. Their application enhances the safety, reliability, and longevity of subsea cable installations across wind energy, oil & gas, and marine communication sectors. As offshore infrastructure continues to expand, reliable bend protection solutions are essential to ensuring uninterrupted and cost-effective subsea operations.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.