The polyurethane renewable joint bend restrictor is a subsea protection device designed to prevent cables, umbilicals, and flexible risers from over-bending in offshore environments. It combines the proven strength of polyurethane with an innovative, renewable joint design, delivering both long-term durability and sustainable performance in marine applications.

Material performance

Hardness range: Shore A85–D65, adjustable to match static or dynamic cable conditions.

Tensile strength: ≥25 MPa, ensuring high resistance against cyclic fatigue.

Tear resistance: ≥80 kN/m, minimizing the risk of crack propagation.

Environmental durability: Excellent resistance to seawater, hydrolysis, oil, and chemicals.

Abrasion resistance: Extends service life in high-contact zones such as J-tube exits and hang-off points.

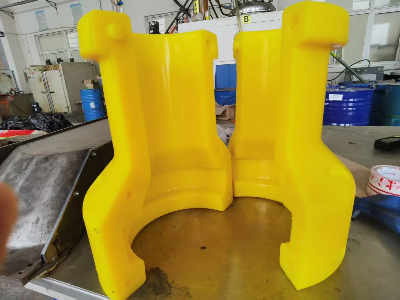

Renewable joint design

Modular interlocking segments: Allow partial replacement instead of full unit removal.

Onshore or offshore installation: Flexible options reduce operational downtime.

Lower lifecycle cost: Damaged sections can be renewed easily, improving cost efficiency.

Sustainability focus: Supports recyclable polyurethane use, aligning with offshore renewable energy initiatives.

Functional advantages in submarine applications

Bend radius control: Ensures cables never exceed their minimum allowable bend radius, reducing fatigue failures.

Dynamic cable protection: Suitable for floating wind turbines, FPSOs, and riser hang-offs exposed to constant motion.

Static reinforcement: Ideal at J-tube and I-tube exits, subsea terminations, and cable landings.

Versatility: Protects subsea power cables, umbilicals, telecom cables, and flexible flowlines across both offshore wind and oil & gas sectors.

Key benefits

Customizable hardness and dimensions for specific offshore projects.

Long-term stability in harsh marine environments.

Renewable modular system reduces waste and simplifies maintenance.

Lower total cost of ownership compared to one-piece bend restrictors.

Environmentally conscious design supports sustainable offshore development.

Elastomer articulated bend restrictor offers reliable cable protection with a future-focused design. By combining polyurethane’s mechanical strength and seawater resistance with a renewable modular joint concept, it delivers safety, cost savings, and sustainability for offshore wind, oil & gas, and subsea power transmission projects.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.