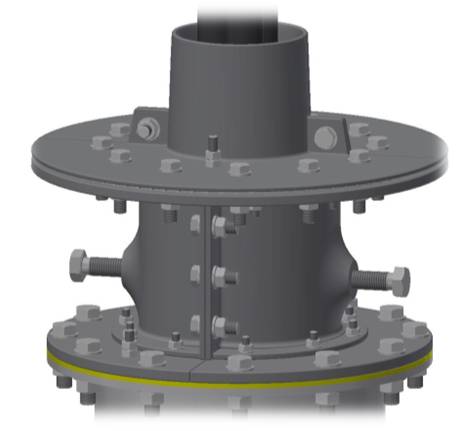

Offshore hang-off clamps connect cables to rigid structures such as electric piles, drilling rig bases, and cable decks. Resin is injected inside, which has good sealing properties and protects offshore wind power, offshore oil platforms, and inter-island power networking cables from seawater corrosion.

The role of marine cable hang-off

Mechanical fixing function: prevent the cable from displacement or sliding under the action of ocean dynamics such as waves and tides, and ensure that the cable remains stable in the predetermined position.

Stress dispersion effect: effectively transfers the tensile load of the cable to the seabed foundation or structure to avoid stress concentration and cable damage.

Anti-corrosion protection: Isolate seawater from corroding cable metal parts and extend the service life of the cable system.

Anti-fatigue design: buffer the cyclic load brought by the marine environment and reduce fatigue damage to cable materials.

Connection transition: provide a smooth stiffness transition at the connection between the cable and the platform, shore base, and other structures to avoid sudden stress changes.

Structural features of resin-type cable hang-offs

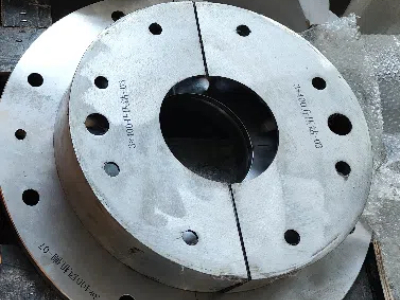

(1)Hang-off body

Made of high-strength 316L stainless steel, it has extremely strong rigidity and corrosion resistance and is suitable for use in saline seawater.

(2) Resin infusion space

The interior is designed with a special texture structure to ensure that the resin evenly fills the hang-off space to enhance the bonding force with the resin.

(3) Stress cone structure

The gradient geometric shape design is adopted to achieve a smooth transition of stress between the cable and the hang-off.

Design features

Modular design: Easy to install and maintain at sea

Adjustability: Adapts to cables of different diameters and types

Non-destructive hang-off: avoid mechanical damage to the cable body

Monitorability: Some high-end designs integrate sensors to monitor the hang-off status

Technical advantages

Compared with traditional mechanical hang-off methods, resin-type cable hang-off has significant advantages:

Stress distribution is more uniform, avoiding local stress concentration

Better fatigue resistance, suitable for a long-term dynamic load environment

Excellent waterproof sealing performance

The installation process is relatively simple, and the quality is easier to control

Low maintenance requirements and long service life

With the continuous deepening of marine energy development, the stability of the cable system is becoming increasingly important. Resin-type cable hang-off is becoming an important means to ensure the safety of marine cable operations due to its advantages, such as high strength, corrosion resistance, and strong adaptability. Hang-off devices suitable for various types and models of cables and base platform structures can be customized.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.