In offshore energy and communication systems, subsea cables serve as vital lifelines, transmitting power and data between offshore platforms, wind farms, subsea equipment, and land-based infrastructure. However, these cables are vulnerable to mechanical stress and bending, particularly at connection points such as J-tubes, I-tubes, and termination units. To ensure long-term reliability and structural integrity, offshore cable bend stiffeners are deployed as essential components for protection.

Role of bend stiffeners in submarine cable protection

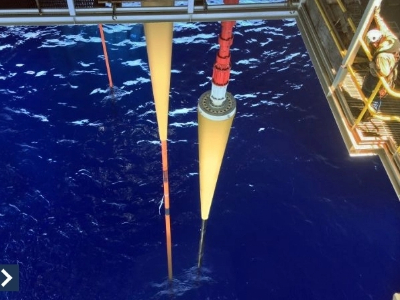

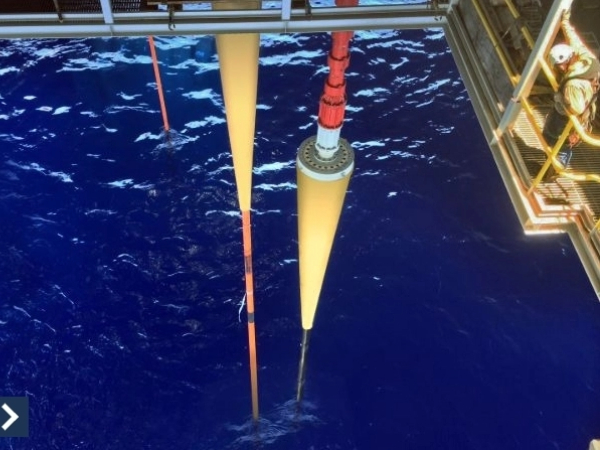

A bend stiffener is a tapered, conical structure—typically made of durable polyurethane—that is fitted at the point where a flexible subsea cable connects to a rigid structure. Its primary function is to prevent excessive bending and reduce mechanical fatigue caused by dynamic loads such as wave motion, currents, or platform movement.

Key functions include

• Preventing overbending and kinking: By gradually increasing stiffness from the flexible cable to the rigid interface, bend stiffeners help maintain a safe bending radius, reducing the risk of damage.

• Fatigue life extension: Bend stiffeners minimize stress concentration at the cable entry point, significantly extending cable service life.

• Environmental resistance: Made of corrosion-resistant, UV-stable, and marine-grade polyurethane, they perform reliably in harsh subsea environments.

• Maintaining structural integrity: They ensure the cable maintains its designed position and curvature during installation and operation.

Applications in submarine power and communication cables

Offshore cable bend stiffeners are widely used across various subsea cable systems, including:

• Subsea power cables

Used in offshore wind farms, oil & gas platforms, and interconnector projects, these high-voltage cables transmit electricity between offshore structures and shore. Bend stiffeners protect them at transition points, such as cable entry into offshore substations or floating platforms.

• Fiber optic communication cables

Subsea communication cables require high reliability to ensure uninterrupted data transmission. Bend stiffeners are used at landing points, repeaters, and subsea equipment interfaces to prevent signal loss due to mechanical stress.

• Dynamic cable systems on floating structures

In floating offshore wind turbines and production units, cables move continuously due to wave and wind motion. Bend stiffeners provide critical strain relief where dynamic cables meet stationary structures.

• Cable riser systems

When cables are routed vertically from the seabed to the platform, bend stiffeners help manage the stress at the top interface, ensuring safe cable curvature.

The offshore cable bending stiffener is a crucial protective device for ensuring the durability and performance of subsea power and communication cables. By controlling bending stress and enhancing fatigue resistance, bend stiffeners play a vital role in safeguarding offshore infrastructure. Whether in renewable energy, telecommunications, or oil and gas, their application is essential for reliable and long-lasting subsea cable systems.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.