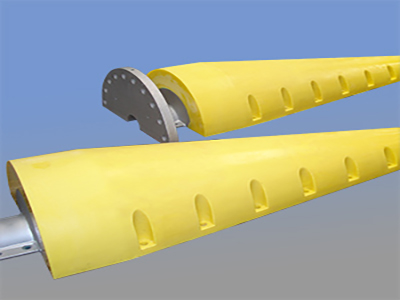

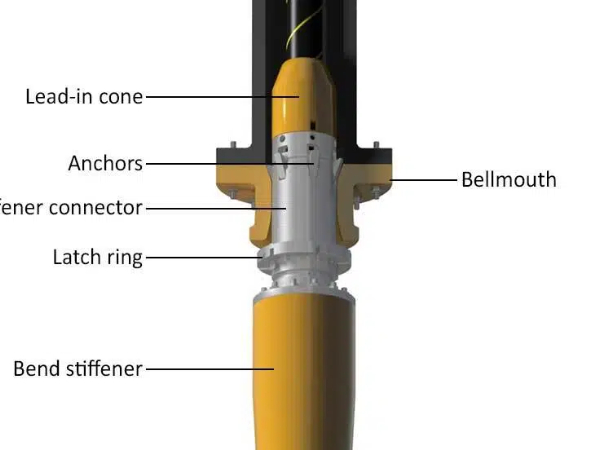

Bend stiffeners support flexible pipes when connecting rigid or floating structures and control the minimum bending radius (MBR). Its special polyurethane material adapts to fluid temperature, pipeline characteristics, stiffness and MBR requirements. It is suitable for dynamic and static scenarios: dynamic needs anti-fatigue bending control, and static prevention of excessive bending. Conical moldings with cylindrical inner holes are sleeved outside the pipe/cable and are often used for top or subsea connections.

Purpose and function of bend stiffeners in flexible pipes

Flexible pipes are used to transport oil, gas, and other fluids in offshore environments. At the connection points—such as where a flexible pipe interfaces with a floating platform or subsea structure—there is a risk of excessive bending due to wave motion, currents, and platform movement. Uncontrolled bending can lead to:

• Pipe fatigue and premature failure

• Cracking or deformation of pipe layers

• Increased maintenance and downtime

A bend stiffener is used to gradually restrict the bending angle, ensuring that the pipe maintains a safe minimum bend radius. This smooth transition reduces mechanical stress, distributes load more evenly, and protects internal components like tensile armor, insulation, and barriers.

Design features

Bend stiffeners are typically manufactured from high-performance polyurethane elastomers, offering:

• Excellent fatigue resistance

• High mechanical strength

• Resistance to seawater and UV degradation

• Elastic flexibility to respond to dynamic motion

• Tailored stiffness profile, designed based on pipe dimensions and operating environment

The geometry is usually conical or tapered to provide graduated stiffness, offering both flexibility at the pipe end and rigidity near the connection point.

Applications in flexible pipe systems

Flexible pipe bend stiffeners are widely used in various offshore and subsea applications:

• Floating production storage and offloading (FPSO) units

• Subsea riser systems

• Dynamic umbilicals and control lines

• Flexible risers and jumpers in deepwater fields

• Wind farm export and inter-array cables

In these systems, bend stiffeners serve as a passive protection mechanism that significantly extends the operational life of pipes exposed to cyclic motion and harsh subsea conditions.

Benefits of using bend stiffeners

• Prevents structural fatigue and damage

• Reduces maintenance frequency and operational risks

• Improves safety in subsea pipeline installations

• Supports compliance with offshore design standards

• Cost-effective solution for lifecycle extension

A bend stiffener is a critical component used in flexible pipe systems, especially in offshore oil and gas and renewable energy installations. It is designed to control the bend radius and provide mechanical support where flexible pipes are connected to rigid structures, such as floating platforms, subsea equipment, or risers. The flexible pipe bend stiffener plays an essential role in protecting pipes from damage due to dynamic environmental loads, ensuring long-term operational reliability.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.