As Vietnam accelerates the development of marine energy resources, especially offshore wind power and oil and gas projects, submarine polyurethane cable bend restrictor has become a key equipment to ensure the safety of submarine cables due to its low density, lightweight, friction resistance, high temperature resistance, and UV resistance. This article combines the characteristics of Vietnam's marine environment and technical needs to analyze from three aspects: product characteristics, core advantages, and typical application scenarios.

Product features

Weather resistance and durability

Polyurethane materials have the characteristics of salt spray corrosion resistance, UV resistance, wear resistance, and flame retardancy. The hardness is generally 80-85D and can be customized. It is especially suitable for Vietnam's high temperature and high humidity marine climate. For example, the polyurethane bend restrictor made by Jiunai Zhizao can achieve a bending life of more than 8 million times, significantly extending the service life of the cable in a dynamic marine environment.

Modular structural design

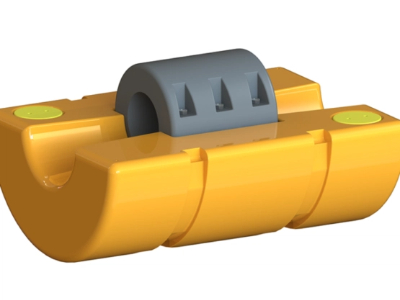

Haval split structure: adopts a symmetrical semi-tube design, which can be quickly assembled through the clamp ring and the clamp slot during installation, simplifying the construction process and adapting to the current situation of limited infrastructure in Vietnam's coastal areas.

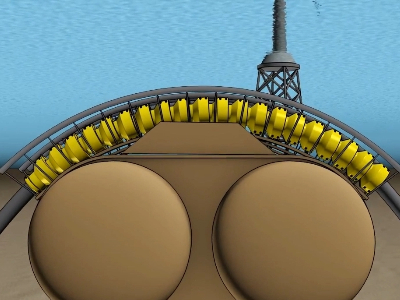

Length scalability: The modular interlocking structure allows the protection length to be increased arbitrarily according to demand. The length of a unit is generally 5 meters and can be customized according to needs. For example, the dynamic cables of the offshore wind farm in Bac Lieu Province, Vietnam need to cover a protection range of tens to hundreds of meters.

Bending space optimization

The combination design of the first half pipe and the second half pipe forms a semi-cylindrical bending space, which can not only provide a larger bending radius (usually ≥3.5 times the cable diameter), but also limit relative rotation through the interference fit between the positioning pin and the positioning hole to ensure the stability of multiple modules in series. For example, the "White Tiger Oilfield" pipeline on the southern continental shelf of Vietnam adopts this type of design in steep slope terrain to effectively avoid the risk of excessive bending.

Core advantages

Lightweight and economical

The density of polyurethane is only 1.03kg/m³, which can reduce the transportation and installation costs by 30% compared with metal materials, especially suitable for budget control of some remote sea projects in Vietnam.

Dynamic load adaptability

Typhoons frequently occur in Vietnamese waters, and cables need to withstand frequent tidal impacts and ship anchoring stress. The high elastic modulus of polyurethane can disperse dynamic loads and reduce fatigue damage. For example, the floating wind power project planned in Ben Tre Province, Vietnam, successfully resisted the 8-ton lateral pressure caused by Typhoon "Dianmu" in 2024 through such limiters.

Standardization and compatibility

The product supports customized processing, with small dimensional errors, and can be adapted to cables of different specifications. For example, the subsea pipeline of Vietnam's "Blue Whale" natural gas project adopts J-type bending limiters, which are seamlessly integrated with auxiliary pipeline channels to achieve multi-system collaborative protection.

Typical application scenarios

Offshore wind power dynamic cable protection

Vietnam plans to achieve a target of 6 GW offshore wind power installation by 2030. Polyurethane bending restrictors are used in the connection section between floating wind turbines and submarine cables to improve the fatigue resistance of deep-sea cables.

Reinforcement of subsea pipelines in oil and gas fields

In oil and gas development projects on the southern continental shelf of Vietnam (such as the White Tiger Oilfield), submarine pipelines need to cope with complex terrain and ocean current impacts. The use of J-type bending restrictors eliminates the risk of bending at steep slopes through mechanical locking structures to reduce oil and gas leakage accidents.

Verification of adaptability to extreme environments

In the wave energy test project "Wave Hub" in Ca Mau Province, Vietnam, the polyurethane limiter integrates intelligent stress sensors to monitor the cable status in real time, providing data support for remote operation and maintenance in typhoon-prone areas in the future.

The application of submarine polyurethane cable bend limiters in Vietnam has shifted from the pilot stage to the scale stage. Its material properties and modular design fully meet the country's marine energy development needs. Chinese polyurethane bend limiters have the characteristics of low cost, high return and low maintenance, helping Vietnam become an important marine engineering protection equipment market in Southeast Asia. If you have any related needs, please contact us.