In Singapore, offshore oil and gas operations rely on robust subsea infrastructure to ensure safe and efficient transfer of control umbilicals, hydraulic lines, and flowlines from seabed installations to platform topsides. Umbilical bell-mouth centralizers are essential components in these systems, guiding and supporting umbilicals as they pass through J-tubes and protecting them from mechanical damage.

Project background

A recent offshore oil and gas project in Singapore involved connecting multiple subsea manifolds to a central production platform via high-pressure umbilicals. The project faced challenges, including complex seabed topography, strong tidal currents, and heavy subsea loads. Effective centralization of umbilicals was critical to maintain cable alignment, prevent over-bending, and ensure long-term operational reliability.

Design considerations and breakthroughs

The design and production of umbilical bell-mouth centralizers for this project required several key considerations:

Precise fit to cable and j-tube: Centralizers were engineered to match the exact diameter of umbilicals and the curvature of j-tubes, ensuring smooth pull-in operations.

High-performance materials: Polyurethane with exceptional wear resistance, impact strength, and seawater durability was chosen to withstand harsh subsea conditions.

Dynamic load management: Centralizers were designed to handle forces from currents, platform movement, and installation stress without deformation.

Friction reduction: Optimized surface design minimized abrasion and pull-in resistance, reducing installation risks.

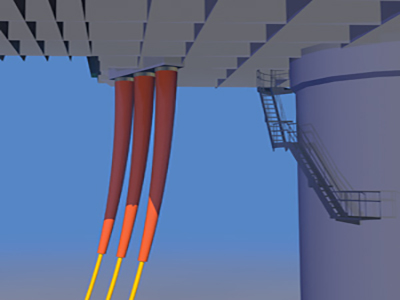

The J-tube is made of two symmetrical half shells fixed with screws. The main body is made of stainless steel, and the front part is polyurethane. The tapered structure makes it easier to pull the umbilical cable into the J-tube flare.

Production breakthroughs

Philson implemented advanced polyurethane molding techniques and rigorous in-house testing to ensure each centralizer met project-specific requirements. Innovations included:

Faster, cost-effective production with tight dimensional tolerances.

Enhanced durability under high hydrostatic pressure and dynamic loads.

Customizable designs are adaptable for various umbilical diameters and subsea environments.

J-tube centralizers play a vital role in offshore oil and gas projects in Singapore. By combining advanced materials, precise engineering, and innovative production methods, these centralizers help ensure safe installation, reliable operation, and long-term protection of critical subsea umbilicals.