In offshore oil, gas, and renewable energy projects, subsea cables and pipelines face multiple risks, including abrasion, dropped objects, over-bending, and seabed interaction. Protecting these assets is critical for ensuring long-term reliability and reducing costly maintenance. This case study examines the application of a split flexible protection sleeve, highlighting its features, adaptability during installation, and successful deployment in marine engineering projects.

Product features

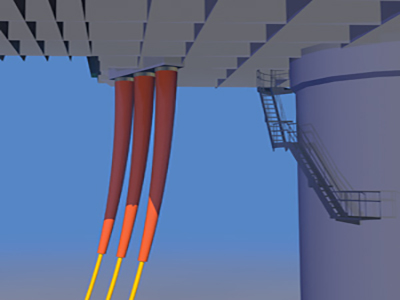

The split flexible protection sleeve is designed to safeguard subsea cables, umbilicals, and pipelines against external damage. Key features include:

• Split design: Enables quick installation without disrupting existing lines, reducing offshore installation time.

• Interlocking structure: Provides robust mechanical protection by creating a continuous, secure barrier around cables or pipelines.

• Polyurethane construction: Manufactured using durable, marine-grade polyurethane with hydrolysis resistance.

• Flexibility: Adapts to cable and pipeline curvature without compromising structural integrity.

• Customizable hardness: Available in 70–85d shore hardness, tailored to project-specific load and impact requirements.

Applicable pipeline types

The protection sleeve has been effectively deployed in multiple subsea asset categories, including:

• Offshore oil and gas pipelines

• Bundled subsea cables and flexible ducts

• Power export cables for offshore wind platforms

• Umbilicals and subsea communication lines

• Fiber optic cables requiring abrasion resistance

Installation locations

One of the strengths of the split flexible protection sleeve is its adaptability to different subsea environments:

• Seabed touchdown zones: Prevents abrasion and bending where cables meet the seabed.

• Dropped object zones: Protects cables and pipelines from falling tools or debris during offshore operations.

• Cable crossings: Ensures protection at points where subsea cables and pipelines intersect.

• Floating offshore wind arrays: Provides touchdown protection for dynamic cables in floating wind projects.

Benefits achieved

• Reduced installation time: Split design allowed for rapid on-site assembly without dismantling existing systems.

• Extended asset lifespan: Prevented premature wear, reducing the risk of cable failure and downtime.

• Versatile application: Adapted to various cable diameters and subsea conditions.

• Enhanced safety: Provided critical protection in high-risk zones, ensuring regulatory compliance.

Conclusion

The polyurethane submarine protective tube has proven to be a cost-effective and highly reliable solution for subsea cable and pipeline protection. Its modular design, polyurethane durability, and adaptability make it indispensable in offshore oil, gas, and renewable energy applications. By mitigating mechanical risks and environmental challenges, it significantly enhances the operational safety and lifespan of critical subsea infrastructure.