Discover how bend restrictors are essential for protecting subsea flexible jumpers from overbending and failure, ensuring durability, safety, and optimal performance in harsh offshore environments.

What is a subsea flexible jumper?

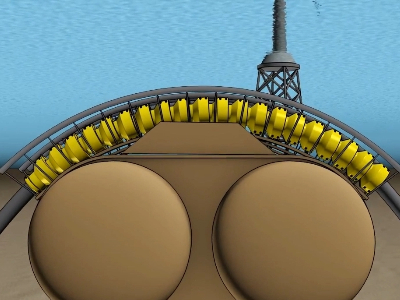

A subsea flexible jumper is a short-length, high-strength flexible pipe designed to connect two subsea components, such as:

Wellheads and manifolds

Flowlines and risers

Subsea trees and export systems

It is used to transport production fluids (oil, gas, or water), injection fluids, or control signals in subsea environments. These jumpers are specially engineered to withstand underwater pressures, currents, and movement, making them ideal for dynamic offshore oil & gas or renewable energy systems.

What is the function and importance of a bend restrictor in a subsea flexible jumper?

A bend restrictor is a mechanical protective device installed around the flexible jumper to limit its minimum bend radius. Its function is critical in preventing overbending, which can lead to:

Fatigue damage

Layer separation or collapse within the flexible pipe

Reduced lifespan or catastrophic failure of the jumper

Key functions

Bending protection

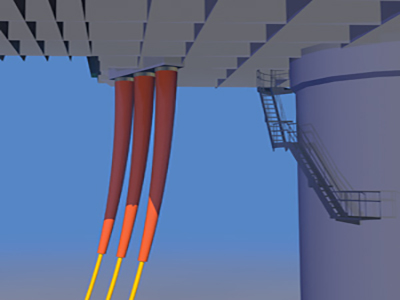

Prevents the jumper from bending beyond its design tolerance during installation or operation, especially near connection points or touchdown zones.

Stress distribution

Distributes mechanical stress across multiple interlocking segments (typically polyurethane), reducing concentration at any single point.

Installation safety

Provides rigid support during overboarding (deployment from the vessel) and seabed landing, minimizing mechanical shock.

Maintaining system integrity

Essential in dynamic environments like floating production systems, where the jumper moves due to wave or platform motion.

Importance in subsea systems

Extends the operational life of the jumper

Reduces maintenance and failure risk

Complies with offshore safety standards

Enables reliable operation in harsh deepwater conditions

A subsea flexible jumper provides adaptable, high-performance fluid transport in subsea applications, while the bend fatigue protection is an essential accessory that ensures mechanical protection, fatigue resistance, and long-term reliability, especially in areas with dynamic loads or tight bend radius requirements.