Polyurethane bend restrictor is a key protective component designed to prevent hoses, submarine cables or umbilicals from being damaged due to excessive bending during installation and operation. Its structural design and material properties make it play an important role in a variety of industrial and marine engineering environments.

Structural features of bend restrictor

1. Modular articulated structure

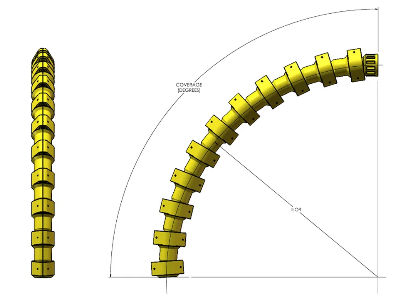

Polyurethane bend restrictors usually adopt a modular design, with multiple interlocking elements hinged together to form a semi-rigid bending structure. This design allows flexible bending within a specific minimum bending radius (MBR) range while preventing the set bending angle from exceeding, thereby protecting the internal pipe or cable. An anti-loosening locking device is set at the interface to ensure stability in a long-term vibration environment.

2. High-performance polyurethane material

The restrictor is mainly made of polyurethane elastomer, which has high wear resistance, tear resistance and excellent elastic recovery ability. Polyurethane materials also have good hydrolysis corrosion resistance and UV resistance, and can work stably and long-term in marine environments.

3. Customizable

According to different application requirements, customized polyurethane bend limiters can be adapted to hoses or cables of different lengths, specifications and types. Hardness and color can also be customized.

Main functions

1. Prevent excessive bending

The limiter limits the bending angle of the hose or cable through its structural design, prevents damage caused by excessive bending during installation, and ensures the safety and reliability of the system.

2. Provide mechanical support

In systems connected to rigid structures or requiring control of the minimum bending radius, the bend limiter provides the necessary mechanical support for the hose or cable and enhances its overall structural strength.

3. Extend service life

By reducing the mechanical stress and fatigue of the hose or cable during operation, the bend limiter helps to extend its service life and reduce maintenance and replacement costs.

Use scenarios

1. Marine engineering

In projects such as offshore oil and gas extraction, submarine cable laying and offshore wind power, polyurethane bend limiters are used to protect submarine cables and umbilicals to prevent excessive bending caused by external forces such as waves and currents.

2. Oil and gas industry

In the oil and gas transportation system, limiters are used to protect flexible pipes to prevent static loads or excessive bending during installation or operation.

3. Industrial applications

In the industrial field, polyurethane bend limiters can be used to protect various hoses and cables, especially in systems that require frequent movement or complex bending paths to ensure their normal operation.

Polyurethane bend limiters play a key protective role in multiple industries due to their unique structural design and excellent material properties. Its modular structure, high-performance polyurethane material and adjustable length design make it an important component to ensure the safe operation of hoses and cables.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.