In modern industrial production and infrastructure construction, the protective performance, adaptability, and versatility of materials directly affect project efficiency, safety, and cost control. As a new type of material with multiple advantages, anti-collision polyurethane sheets are gradually penetrating the core scenarios of various industries — whether reducing mechanical operation noise, constructing efficient thermal insulation layers, bearing heavy equipment, or blocking pollutant erosion, they all play a key role. They have become an indispensable core material in fields such as aerospace manufacturing, engineering construction, marine engineering, national defense, food services, and the automotive industry. According to the working condition requirements of different industries, standard models can be accurately selected or customized polyurethane sheets can be tailored to achieve a perfect match between performance and scenarios.

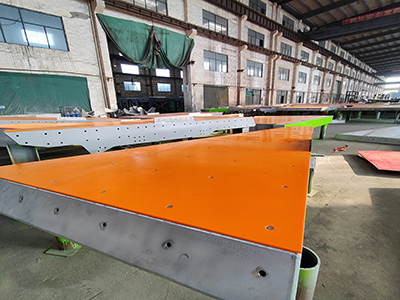

Marine-Grade Anti-Collision Polyurethane Sheets

Targeting extreme working conditions such as marine environments, Philson launches marine-grade anti-collision polyurethane sheets. With excellent weather resistance, corrosion resistance, and anti-collision performance, they have become the ideal choice for scenarios such as shipbuilding, offshore platforms, and port facilities. They can effectively resist seawater erosion, wind and wave impact, and marine biofouling, while reducing collision damage and noise pollution during ship berthing and equipment transfer, providing comprehensive protection for the safe and stable operation of marine engineering.

Core Characteristics of Polyurethane Sheets

The reason why polyurethane sheets can cover multiple industrial scenarios lies in their comprehensive and outstanding core characteristics, with each performance precisely addressing key pain points in practical applications:

Sealing Protection: Possesses excellent sealing performance, which can effectively block the penetration of gases and liquids, adapting to the sealing needs of equipment interfaces and pipeline connections.

Noise Reduction: Its elastic structure can absorb vibration and impact energy, significantly reducing noise during mechanical operation and material transmission, and optimizing the production environment.

Thermal Insulation: The dense internal structure forms an efficient thermal insulation layer, which can reduce heat conduction, adapting to the thermal insulation needs of industrial equipment and building walls, and reducing energy consumption.

Superior Load-Bearing Capacity: Features dual high-strength load-bearing performance, capable of stably supporting high-pressure scenarios such as heavy equipment and material stacking without deformation or damage.

Shock Absorption and Buffering: Excellent vibration damping performance, which can absorb vibrations generated by equipment operation or external impact, protecting precision instruments and the structure itself.

Comprehensive Corrosion Resistance: Has resistance to wear, moisture, oil, mold, and many potentially corrosive chemicals, adapting to complex corrosive environments such as industrial oil pollution and chemical workshops.

Specifications and Parameters of Polyurethane Sheets

To meet the refined needs of different industries and scenarios, Philson provides a wealth of standard specifications and flexible customization services, with hardness, size, and color all adjustable on demand:

Hardness Options: Covers multiple hardness levels to adapt to different force-bearing and elastic needs:

Shore 00 (soft range): 10, 20, 30, 40, 50, 60, 70 (suitable for buffering, sealing, and other scenarios);

Shore A (medium-hard range): 10, 20, 30, 40, 50, 60, 70, 80, 90, 95 (suitable for protection, load-bearing, and other scenarios);

Shore D (hard range): 40, 50, 60, 70, 80 (suitable for high-strength support, wear resistance, and other scenarios).

Size Specifications: Thickness starts from 1mm, with standard sheet sizes including 1000×1000mm, 1200×1200mm, and 1500×1500mm; arbitrary size customization is supported, which can be accurately cut according to equipment specifications and installation space without additional adaptation and modification.

Color Options: Regular colors include yellow, black, red, blue, and white, and customized exclusive colors are also available to meet the needs of industry identification, environmental matching, or brand unification.

Customization Services: Hardness, size, color, and thickness can all be tailored according to the customer's specific working conditions and usage requirements. Whether it is a special shape, ultra-high hardness, ultra-large size, or specific corrosion resistance and high-temperature resistance requirements, precise solutions can be provided to achieve one product for one scenario.

Conclusion

Polyurethane sheets and various types of polyurethane products, with their excellent load-bearing capacity, chemical resistance, flexibility, and customization advantages, accurately meet the diverse needs of modern industry and have become an indispensable key material in the manufacturing process. As a leading polyurethane sheet supplier, Philson is committed to providing high-quality polyurethane solutions. With rich industry experience, advanced production technology, and flexible customization services, it solves practical pain points for customers in fields such as aerospace, marine, automotive, and engineering, driving industry innovation and efficiency improvement.

Whether you need standard conventional products or customized solutions for special working conditions, Philson can provide you with accurately adapted solutions. Welcome to contact us at any time to jointly explore more application possibilities of polyurethane sheets in your industry scenarios!

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.