The standout properties of flexible PU sheets—particularly their shock absorption, abrasion resistance, and flexibility—make them a staple in the marine industry, where materials must withstand saltwater corrosion, UV radiation, and extreme temperature fluctuations. Their ability to resist water absorption and maintain performance in harsh marine environments positions them as a top choice for critical components:

Boat Fenders & Docking Equipment: Flexible PU sheets absorb kinetic energy during vessel docking, protecting both the boat hull and docking infrastructure from impact damage. Their wear resistance ensures long-term performance even with frequent use in high-traffic ports.

Flotation Devices: Thanks to inherent buoyancy and low water absorption, flexible PU sheets are used in life jackets, buoyancy aids, and marine safety equipment—delivering reliable flotation without compromising on flexibility or comfort.

Marine Seals & Gaskets: Their elasticity allows flexible PU sheets to form tight, durable seals around hatches, windows, and hull joints, preventing water intrusion while withstanding constant exposure to saltwater and humidity.

Beyond marine applications, flexible PU sheets excel in automotive interior cushioning, industrial conveyor belts, and sports equipment—leveraging their moldability to fit complex shapes and custom dimensions.

Rigid Polyurethane Sheets: Industrial Strength & Insulation

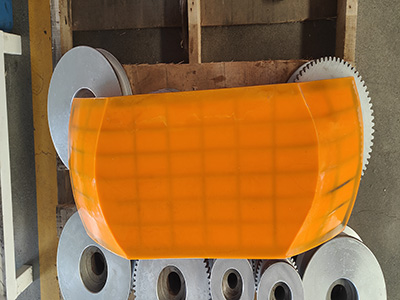

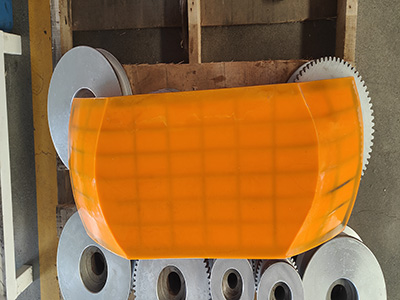

Rigid PU sheets are the material of choice for applications demanding structural strength, insulation, and resistance to harsh industrial conditions. Their hardness, chemical resistance, and dimensional stability make them ideal for protecting machinery, enhancing energy efficiency, and supporting heavy-duty operations across sectors:

Industrial Machinery Protection: As protective covers, shields, and component housings for manufacturing equipment, rigid PU sheets withstand abrasion, chemical spills, and mechanical impacts—reducing maintenance costs and extending equipment lifespan in factories, mining sites, and heavy industries.

Thermal Insulation Systems: In construction and industrial HVAC, rigid PU sheets deliver superior insulation performance, minimizing heat transfer and improving energy efficiency in buildings, cold storage facilities, and industrial pipelines.

Structural Components: Their high compressive strength allows rigid PU sheets to serve as load-bearing components in lightweight structures, such as industrial shelving, equipment frames, and transportation containers—combining strength with weight reduction.

Why Chinese PU Sheet Suppliers Lead the Global Market

Chinese suppliers have risen to prominence in the global polyurethane sheet market due to three core advantages: customization capabilities, quality control, and supply chain efficiency. Leading manufacturers like Philson, for example, specialize in tailoring PU sheets to client specifications—adjusting thickness, hardness, color, and surface treatments to meet unique application needs. This flexibility, paired with rigorous quality testing (ensuring compliance with international standards for marine, industrial, and automotive use), has earned Chinese suppliers a reputation for reliability.

Additionally, China’s integrated supply chain—from raw material production to advanced manufacturing and global logistics—enables competitive pricing without compromising quality, making Chinese PU sheets accessible to businesses worldwide.

Conclusion: The Indispensable Role of PU Sheets

Flexible and rigid polyurethane sheets continue to redefine material performance across industries, driven by their customizable properties and durability. As a leading supplier, China’s ability to deliver high-quality, application-specific PU solutions has positioned it at the forefront of the global market. For manufacturers seeking cost-effective, reliable materials—whether for marine fenders, industrial machinery protection, or insulation—polyurethane sheets remain a proven choice, with Chinese suppliers standing ready to meet diverse industry demands.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.