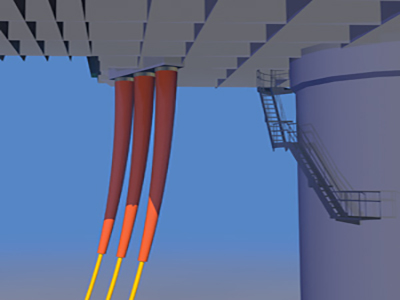

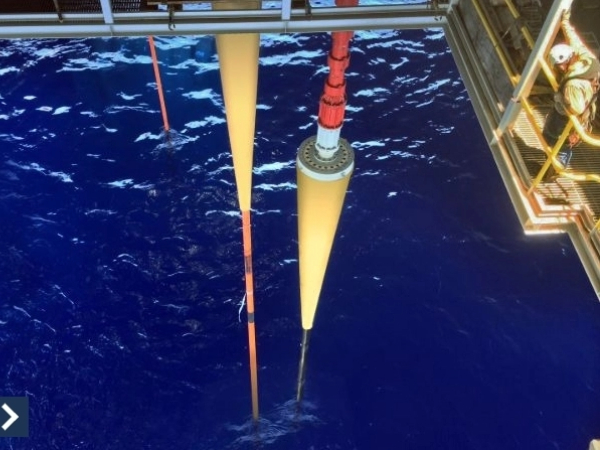

In offshore energy projects such as wind farms, oil and gas platforms, and subsea power transmission systems, J-tube systems are widely used to guide and protect subsea cables as they transition from the seabed into offshore structures. However, this cable entry point is subject to high mechanical stress and repeated movement due to waves, currents, and platform motion. To prevent overbending and ensure the integrity of the cable system, submarine bending stiffeners are installed at these critical interfaces.

The role of bending stiffeners in J-tube systems

Bending stiffeners are conical, tapered devices designed to control the curvature of a subsea cable where it transitions from a flexible to a rigid structure, such as a J-tube or i-tube. Installed at the termination zone, they distribute mechanical loads more evenly and provide gradual stiffness change, protecting the cable from sharp bends and fatigue failure.

Key functions

Prevents overbending at the cable entry point

Reduces dynamic stress from wave and vessel motion

Improves long-term fatigue resistance

Enhances cable stability during installation and operation

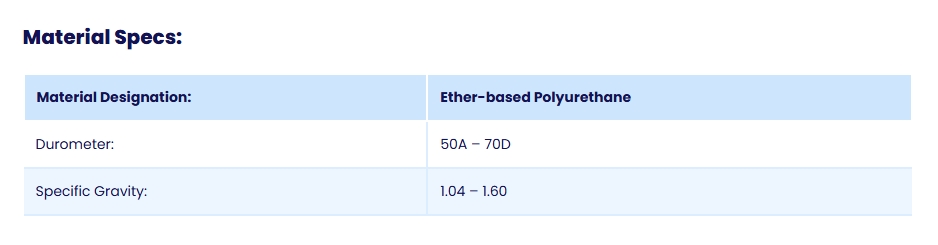

Polyurethane bending stiffeners – material advantages

Our offshore cable bending stiffeners are made from high-performance polyurethane elastomers, chosen for their superior mechanical properties and durability in marine environments.

Material highlights

Hardness range: Shore 50A–70D – offering the ideal balance between flexibility and stiffness to absorb dynamic loading without cracking or deforming

Excellent corrosion resistance – unaffected by seawater, UV exposure, oil, and most offshore chemicals

High tensile strength and elongation – resists tearing and mechanical degradation under repeated stress

Temperature and environmental stability – suitable for long-term deployment in harsh subsea conditions

Customizable design for different cable sizes

Submarine cable systems vary greatly in diameter and mechanical properties depending on their purpose—power transmission, control, or fiber-optic communication. Our J-tube system bend stiffeners can be custom-engineered to match different cable diameters, stiffness levels, and project-specific interface geometries.

We offer

• Custom cone angle and length

• Tailored stiffness profiles based on cable design

• Multiple attachment options are compatible with standard J-tube designs

Application areas

• Offshore wind farms – protecting dynamic export and inter-array cables at the platform interface

• Oil & gas platforms – securing umbilicals and power cables entering topside equipment via j-tubes

• Subsea substations and converters – ensuring cable reliability in floating or fixed offshore structures

The submarine bending stiffener is a critical protective component in modern J-tube systems. Engineered from robust polyurethane materials with high hardness and anti-corrosion capabilities, they offer reliable offshore cable entry protection. With flexible customization options and proven performance in harsh marine environments, polyurethane bend stiffeners are essential for enhancing the durability and safety of subsea cable systems.