In offshore oil and gas development and offshore wind power projects, flexible riser buoyancy is a key component to ensure the stable operation of the riser system. It provides appropriate buoyancy support, controls the catenary shape of the riser in the water, reduces the impact of environmental loads on the pipeline system, and ensures its safety and durability.

Function

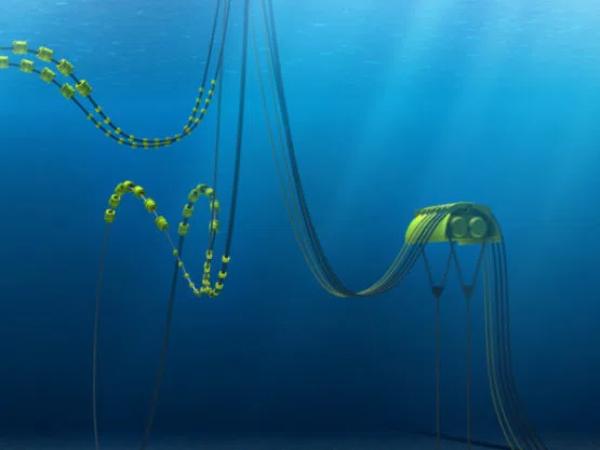

Control the riser shape: The flexible riser buoyancy module adjusts the force and floating state of the riser to form a predetermined catenary configuration (such as Lazy Wave, Steep Wave, etc.) to adapt to different water depths, platform movements, and operation requirements.

Reduce fatigue damage: The buoyancy device can effectively reduce the dynamic stress of the riser under the action of waves and ocean currents and extend its service life.

Avoid seabed contact: By lifting the middle section of the riser, it is prevented from directly contacting the seabed to avoid structural damage such as wear and stretching.

Improve system reliability: Help the riser avoid obstacles or other equipment, avoid collisions and interference, and improve the overall layout safety.

Structural design

Flexible riser buoyancy modules usually adopt a modular clamping design. The material is mainly high-density closed-cell polyurethane or composite foam material, which has good pressure resistance and seawater corrosion resistance. Typical structural designs include:

Clamshell structure: The buoyancy module is two semicircular or fan-shaped structures, which are fixed around the riser by bolts or buckles without affecting the riser body structure.

Multi-section combination design: The module can be installed in sections, which is convenient for transportation and deployment to meet different buoyancy requirements.

Lining protective layer: The contact surface with the riser is usually equipped with a flexible anti-slip layer or wear-resistant lining to avoid damage to the outer wall of the riser.

General and customized coexist: The size and layout can be customized according to the riser diameter, water depth, buoyancy requirements, etc., to ensure the best adaptability.

Use scenarios

Flexible riser buoyancy modules are widely used in the following marine engineering fields:

Riser connection between FPSO (Floating Production Storage and Offloading) or semi-submersible platform and subsea production system;

Deepwater offshore oil and gas development projects require precise adjustment of riser buoyancy according to water depth and environmental loads.

A flexible transmission cable system for offshore wind farms to form an appropriate catenary structure and reduce tension.

Dredging operations or mobile floating equipment to flexibly adjust the path and suspension state of underwater pipelines;

Dynamic riser system optimization in extreme environment deployment scenarios, such as large waves and high flow areas.

Philson specializes in engineering solutions for floating production systems (FPS). Our floating production system components include bending stiffeners, buoyancy modules, subsea umbilical terminal assemblies (SUTA), and steel, polyurethane, and hybrid vertebral bend limiters (VBR) for subsea production systems. Please contact our team of experts to discuss your specific needs.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.