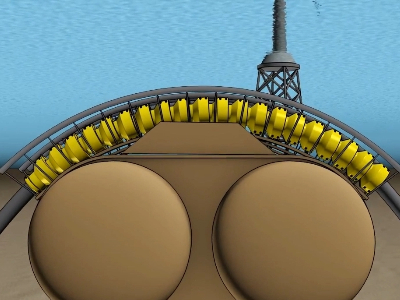

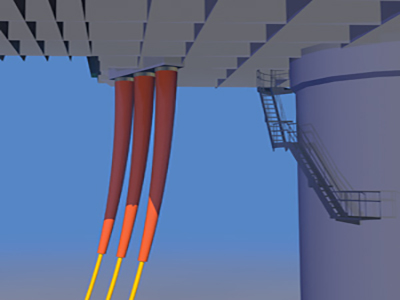

The cable buoyancy module is a cost-effective module designed to achieve optimal performance of dynamic inter-array and export cables of floating offshore wind turbines (FOWTs), providing additional buoyancy and avoiding excessive bending of the cables.

Structural characteristics of the buoyancy module

Floating cable buoyancy modules usually adopt a modular design to balance flexibility and reliability, and are easy to transport and install; their core structure includes:

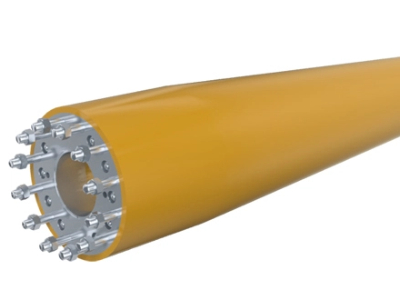

1. Lightweight and high-strength composite shell

Material selection: polyurethane (PU), which has low density, high corrosion resistance, and impact resistance.

Surface treatment: Add anti-biological attachment coating (such as silicon-based materials) to reduce buoyancy loss caused by attachment of marine organisms such as barnacles and algae.

2. Internal buoyancy core

Closed-cell foam material: polyurethane foam, which prevents water penetration through a closed-cell structure and maintains buoyancy stability for a long time.

Density control: The density of the buoyancy material is usually less than 300 kg/m³, ensuring that a single module can provide a net buoyancy of 100-500 N/m.

3. Integrated connection system

Mechanical lock: The modules are connected by slots or bolts, which is convenient for quick installation and replacement.

Cable fixing groove: Rubber pads or polymer straps are used to prevent metal parts from directly contacting the cable and causing wear.

4. Non-standard customization

Customizable size and buoyancy level: Match the buoyancy level according to the cable diameter, specific gravity, and use depth to ensure the optimal bending radius and deployment form.

5. Intelligent monitoring integration (optional)

High-end buoyancy modules have built-in sensors to monitor buoyancy distribution, module integrity, and cable stress in real time, and transmit data through underwater communication systems to achieve preventive maintenance.

Technical advantages of buoyancy modules

1. Extend cable life

Optimized buoyancy distribution can make the cable's bending radius always greater than the design threshold (usually ≥3 meters), avoiding excessive bending and causing insulation cracks or conductor breakage.

Reduce friction with the seabed, reduce sheath wear rate, and extend the operation and maintenance cycle to more than 25 years.

2. Improve system economy

Compared with traditional steel counterweight solutions, the buoyancy module can reduce the total weight of the cable by 30%-50%, saving the cost of installation and ship hoisting.

Modular design supports partial replacement, avoids the scrapping of the entire cable, and reduces the cost of the entire life cycle.

3. Enhance environmental adaptability

Corrosion-resistant materials can resist corrosive media such as salt spray and hydrogen sulfide, and adapt to highly corrosive seas.

Wide temperature range performance (-30℃ to 80℃) ensures stability in the Arctic Circle or tropical waters.

4. Support deep-sea deployment

The buoyancy module enables the cable to adapt to floating wind farms with a water depth of 100-1000 meters, breaking through the water depth limit of fixed platforms (usually <60 meters).

High-performance polyurethane cable buoyancy modules provide key cable protection support for floating wind turbines and are the basic supporting equipment to ensure the safe and stable operation of wind power systems.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.