The importance of submarine cable protection

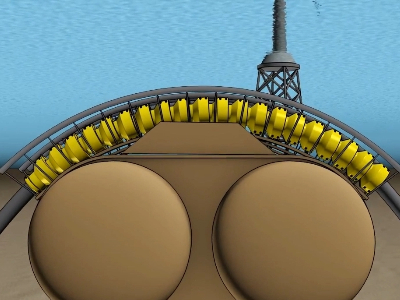

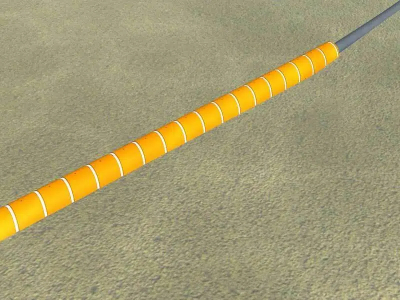

In offshore wind farms, oil and gas fields, and undersea infrastructure, submarine cables are the lifelines of energy transmission and communication. However, these critical assets are constantly exposed to threats such as mechanical impact, seabed abrasion, tidal currents, and stress related to installation. That’s where polyurethane submarine cable protection tubes come into play.

The role of polyurethane cable protection tubes

Polyurethane protection tubes serve as underwater cable protectors, ensuring that power cables, umbilicals, and fiber optics remain intact throughout their service life. Features of these protection sleeves:

• Prevent excessive bending and localized compression

• Absorb impact and vibration

• Reduce friction against steel structures or the seabed

• Extend the life of offshore and subsea cable systems

Their modular or split-sleeve design allows for easy installation during both topside and subsea operations, while the inherent elasticity and wear resistance of polyurethane offer superior protection even in harsh marine conditions.

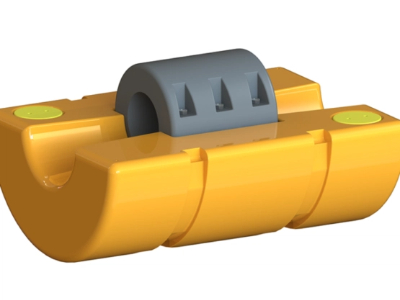

Structural features of polyurethane subsea cable protectors

Material: High-performance polyurethane with customizable hardness (typically 80–95 shore D), friction, and corrosion-resistant. Polyurethane material is lighter.

Design: Split-tube, snap-fit, or bolted structures for fast on-site assembly

Customization: Tailored to specific cable diameters (e.g., 130mm–310mm) and environmental loads

Advantages of Chinese manufacturers

Chinese manufacturers, such as Philson, have emerged as reliable and competitive partners in the offshore cable protection industry. Here’s why:

• Advanced manufacturing capabilities

Equipped with large-scale polyurethane casting facilities, CNC machining centers, and in-house mold-making, Chinese manufacturers can quickly produce high-precision protection sleeves in large volumes.

• Cost-effective solutions

Thanks to efficient supply chains and optimized production processes, Chinese factories offer competitive pricing without compromising quality—ideal for EPC contractors and offshore developers managing tight budgets.

• Flexible customization

From prototype development to high-spec production runs, Chinese manufacturers can rapidly adapt designs based on international project standards and client-specific requirements.

• Global supply experience

Chinese submarine cable protection providers have supplied projects in Europe, Southeast Asia, the Middle East, and beyond, offering export-ready solutions with proven offshore performance.

Choose Philson for your offshore cable protection needs

As a leading Chinese supplier of polyurethane subsea cable protection tubes, Philson offers customized solutions for subsea power cables, J-tube entries, and underwater installations. With strong r&d, fast delivery, and international experience, we help protect your critical infrastructure below the surface.

Contact us today for technical consultation, design assistance, or a competitive quote for your next offshore wind or subsea energy project.