The sealed hang-off system is a critical component in offshore wind farm construction, specifically designed to anchor, seal, and protect subsea power cables where they interface with the topside platform. These systems are typically installed at monopile entries, transition pieces, or floating foundations, ensuring both mechanical and environmental integrity of the cable termination point.

A key feature of the sealed hang-off system is its ability to prevent seawater vapor intrusion, which can lead to corrosion of cable armor layers and surrounding metal structures. The interior is filled with polyurethane sealing compound, which hardens around the cable to provide strong fixation and a watertight barrier.

Structural features

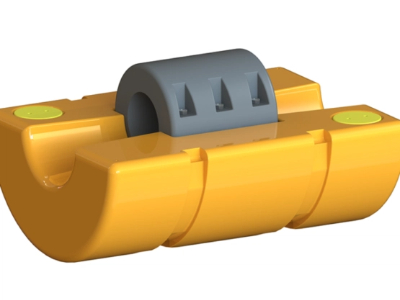

• Split symmetrical design

The hang-off body is designed as a two-piece split clamp, enabling installation around pre-laid cables without cutting or disconnecting them. This simplifies offshore operations and reduces installation time.

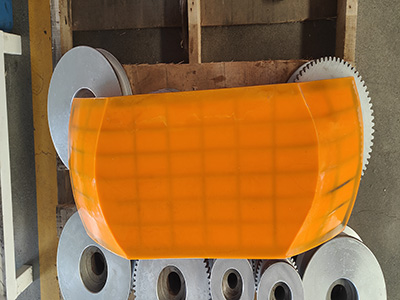

• 316L stainless steel construction

The main body is fabricated from marine-grade 316L stainless steel, offering superior corrosion resistance even in harsh saltwater environments, thus extending the system's operational life.

• Polyurethane injection chamber

The inner cavity is engineered to be filled with liquid polyurethane glue, which sets to form a durable seal around the cable. This method ensures high holding strength and blocks moisture ingress.

• Integrated cable support and grip mechanism

Optional inserts or grip rings provide additional mechanical locking, helping to manage the cable's weight and minimize movement under wave and wind loads.

Main functions

• Cable fixation

Provides secure mechanical support for vertical or angled cables in offshore wind installations.

• Sealing and moisture protection

Blocks seawater vapor and airborne moisture from entering the cable interface zone.

• Corrosion prevention

Prevents premature damage to cable armor and adjacent structural components by eliminating exposure to marine vapor.

• Stress distribution

Evenly distributes cable loads to prevent damage during operation or in extreme weather conditions.

Application scenarios

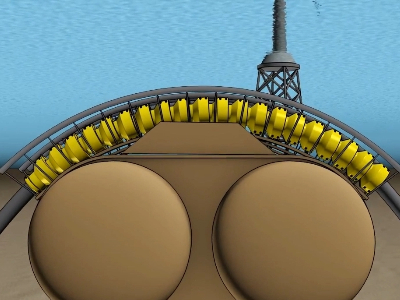

• Monopile offshore wind foundations

Mounted at the upper part of the monopile bases, where export or inter-array cables enter the tower.

• Jacket foundations

Applied at junction boxes or topside plates in multi-leg jacket platforms.

• Floating wind platforms

Suitable for semi-submersible or tension leg platforms to secure dynamic cable risers.

• Transition pieces

Integrated into the cable management interface between the subsea section and tower structure.

Key advantages

• Easy offshore installation with split design

• Long-term corrosion resistance

• High sealing performance with polyurethane filling

• Customizable to suit different cable diameters and foundation types

• Ideal for both fixed-bottom and floating wind applications

Optional customizations

• Cable diameter range: ø60–200mm, other sizes can also be customized.

• Sealant material: High-strength marine-grade polyurethane or epoxy

• Surface treatment: Pickling, passivation, or coating for extreme environments

• Additional grounding, locking plates, or riser clamps upon request.

As offshore wind farms expand into deeper waters and harsher environments, the reliability of cable sealing and support systems becomes increasingly vital. Philson’s sealed hang-off systems provide a robust, corrosion-resistant, and easy-to-install solution for securing subsea power cables in both fixed and floating wind platforms. With durable materials, smart split design, and high-performance polyurethane sealing, our hang-off devices ensure long-term protection and operational stability. Contact us today to customize a hang-off system tailored to your wind energy project requirements.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.