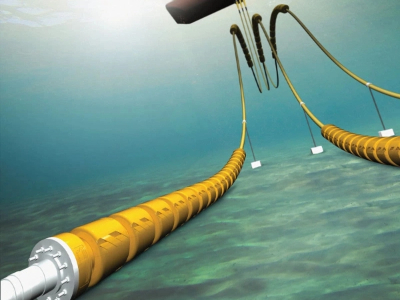

Submarine bend restrictors are widely used in offshore wind turbines and oil platforms. They utilize a modular structure and marine-grade, hydrolysis-resistant polyurethane material, making them lightweight and corrosion-resistant. They prevent excessive bending in submarine cables, provide high strength, and offer a service life of over 28 years.

Applications

Submarine bend limiters are primarily used during submarine cable construction or under special operating conditions to protect cables from excessive bending. Typical applications include:

Offshore oil platforms and offshore wind turbine projects

J-tube lower ports, used with J-tube seals or J-tube center clamps

Bend limiters installed at strategic locations effectively prevent damage to submarine cables caused by excessive bending, ensuring safe operation in complex marine environments.

Structure and features

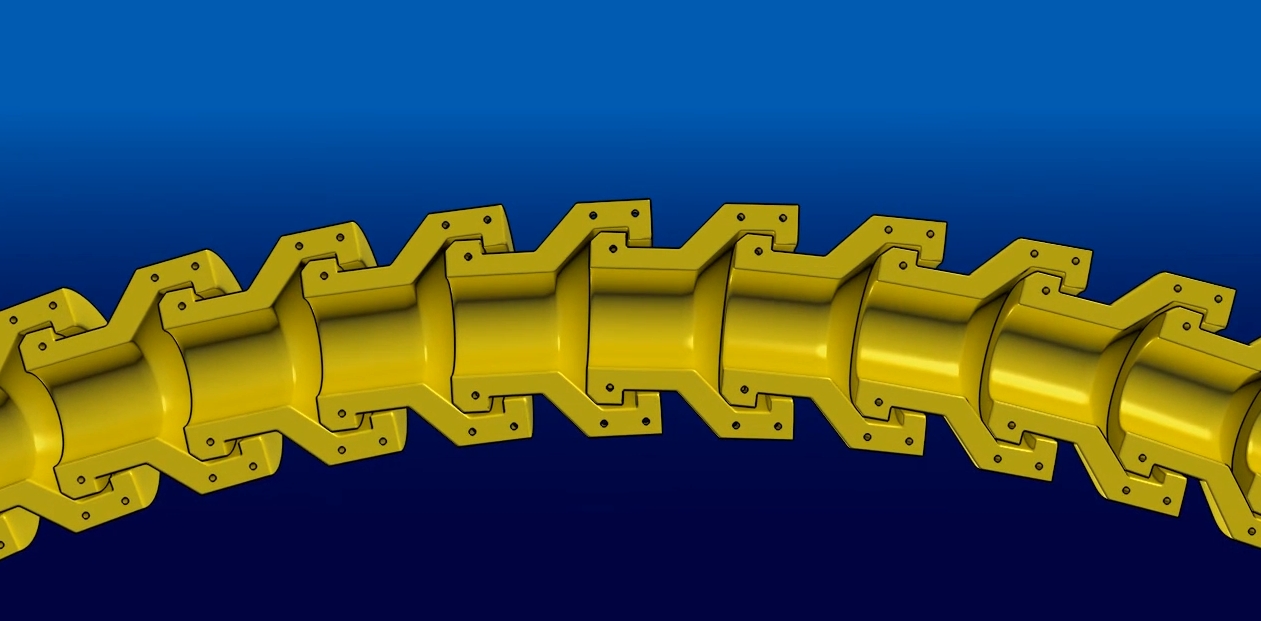

• Modular haver structure

Units interlock to form a chain-like structure, allowing for flexible movement between adjacent units. When stressed, they automatically lock, creating a defined minimum bend radius and ensuring the cable does not exceed the safe bending range. High-Performance Materials

Utilizing NDI series polyurethane specifically formulated for marine applications, this material offers excellent deformation resistance and mechanical strength, ensuring stable long-term performance.

• Lightweight design

With a material density of 1.17 g/cm³, this cable is lightweight, easy to install, and poses virtually no additional load to the submarine cable underwater.

• Corrosion-resistant fasteners

Utilizing super-duplex stainless steel fasteners, this cable offers excellent corrosion resistance in marine environments, ensuring a product lifespan of at least 28 years.

Key technical parameters

• Common specifications: ID130, ID150, ID170, ID260, suitable for 35kV, 110kV, and 220kV submarine optical fiber composite cables

• Locked bend radius: ≥ 20 times the cable's outer diameter

• Lateral compressive strength: ≥ 8 tons

• Lateral impact resistance: ≥ 1000 Nm

• Breaking bending tensile strength: ≥ 1 ton

• Service life: ≥ 28 years

With its modular design, high-performance polyurethane material, and excellent corrosion resistance, bend fatigue protection provide a solid guarantee for the safe operation of submarine cables in wind power, oil, and deep-sea projects. Their precise mechanical properties and long life make them an indispensable cable protection component in the marine energy sector.