In the challenging field of offshore engineering, from subsea cables to dynamic risers, countless critical components serve as the "lifelines" of the deep sea, carrying out the essential missions of energy transmission and signal communication. However, these flexible components are constantly threatened by the harsh marine environment—including current impacts, wave loads, and complex seabed topography. Offshore engineering bend restrictors are specialized protective devices designed precisely for this purpose, utilizing rigid "armor" to ensure the stable operation of deep-sea equipment under extreme conditions.

1. What is an Offshore Engineering Bend Restrictor?

An offshore engineering bend restrictor is a mechanical protection device specifically designed for marine environments. Typically constructed from corrosion-resistant materials such as high-performance polyurethane, composite materials, or stainless steel, it features a modular link structure. Its primary function is to enforce a minimum bend radius on subsea cables, flexible risers, and similar components, preventing internal structural damage, armor layer fractures, or seal failure caused by excessive bending.

2. Why Are Bend Restrictors Essential in Offshore Engineering?

Resisting Dynamic Marine Loads:Currents and waves induce repetitive oscillations in subsea cables or risers. Bend restrictors eliminate the risk of over-bending through mechanical limiting, preventing metal fatigue or fiber-optic breakage.

Preventing Installation and Operational Damage:During cable or riser installation, bend restrictors help avoid "kinking" from sharp bends. In long-term operation, they reduce abrasion and wear caused by contact with the seabed or platform structures.

Adapting to Complex Seabed Terrain:In rugged seabed areas such as cliffs or rocky zones, bend restrictors provide rigid support for suspended pipeline sections, preventing localized stress concentration.

Extending Service Life:By reducing bending fatigue and external wear, they significantly lower maintenance frequency and replacement costs—especially critical for subsea cables that can cost tens of millions per kilometer.

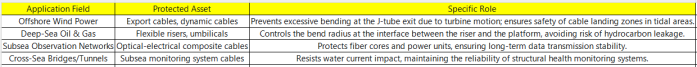

3. Key Application Scenarios: From Offshore Wind Power to Deepwater Oil & Gas

4. Technological Trends: Integration and Intelligence

The next generation of bend restrictors is evolving toward lightweight composite materials and integration with monitoring systems (e.g., embedded bend sensors), upgrading from "passive protection" to "condition-aware" functionality. This advancement provides valuable data support for intelligent operation and maintenance.

Conclusion

Driven by the national marine development strategy and the transition to clean energy, bend restrictors—though small components—are foundational to ensuring the safe operation of large-scale offshore engineering systems. Their technological evolution directly impacts China’s deep-sea exploration capabilities and the reliability of offshore energy infrastructure.