In offshore wind farms, subsea power cables play a critical role in transmitting electricity from turbines to substations and ultimately to the onshore grid. These cables are subjected to constant motion, wave-induced forces, and mechanical stress, especially at connection points. To ensure long-term performance and reduce the risk of damage, bend stiffeners are used as a key protective component in offshore cable systems.

Installation location of bend stiffeners

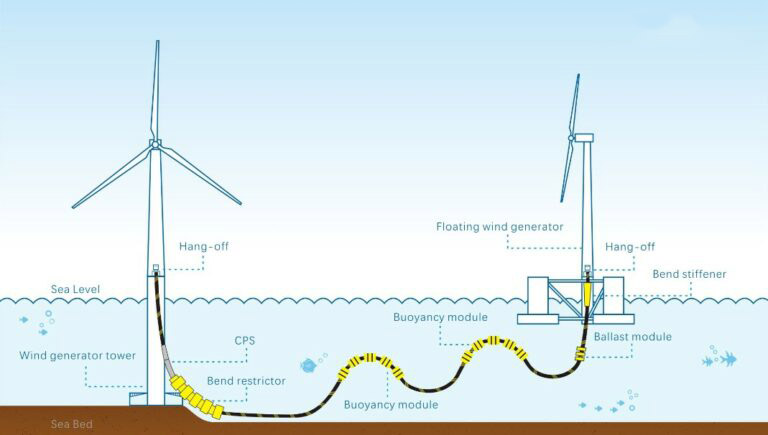

Bend stiffeners are typically installed at cable termination points, where a flexible cable interfaces with a rigid structure. Common locations include:

• The point where the cable exits a J-tube on a platform or transition piece.

• The connection between a dynamic cable and a subsea umbilical or flowline.

• The cable interface at the base of an offshore wind turbine foundation or substation.

Their conical shape and gradually increasing stiffness help control the cable’s bending radius, particularly in dynamic zones where wave and current motion can cause repeated flexing.

Function of bend stiffeners

The primary function of a bend stiffener is to protect subsea cables from excessive bending, which can lead to fatigue damage and insulation failure. Specifically, bend stiffeners:

• Limit cable curvature to remain within safe design limits.

• Distribute mechanical stress over a larger area to reduce concentration at the cable connector.

• Absorb wave and tidal motion, preventing continuous flexing of the cable at fixed points.

• Enhance the fatigue life of the cable in dynamic applications by reducing stress cycles.

In dynamic offshore environments, especially in floating wind farms or locations with high wave activity, bend stiffeners are a critical element of cable integrity management.

Advantages of using bend stiffeners

• Extended cable lifespan

By maintaining a controlled bend radius, bend stiffeners reduce fatigue and prevent early failure of cable insulation or armor layers.

• Cost-effective damage prevention

Cable repairs in offshore environments are costly and time-consuming. Bend stiffeners help prevent mechanical damage, reducing maintenance and downtime.

• Customizable for project requirements

Manufactured from high-performance polyurethane elastomers, bend stiffeners can be customized in terms of length, stiffness profile, and hardness to suit different cable diameters and environmental conditions.

• Durability in harsh marine environments

Polyurethane bend stiffeners offer excellent resistance to UV radiation, saltwater, and hydrolysis, ensuring long-term durability under submerged conditions.

• Compatibility with various cable types

Whether used with high-voltage export cables, dynamic array cables, or fiber optic cables, bend stiffeners can be adapted to meet the demands of various offshore wind farm configurations.

Bending stiffeners are an essential component in the design of offshore wind farm cable systems. Installed at critical transition points, they prevent cable damage caused by excessive bending and mechanical stress. With their durable materials, customizable designs, and proven performance, polyurethane bend stiffeners contribute to the overall reliability, safety, and cost-efficiency of offshore wind power infrastructure.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.