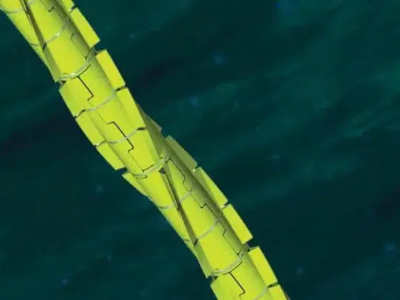

Vortex-induced vibration (VIV) strakes consist of overlapping, interlocking modules with a three-headed helix design, creating a stable triangular or trapezoidal profile. They effectively disrupt and disperse high-speed horizontal water flow downward, thereby preventing vibration in pipes or risers.

Why are VIV strakes necessary?

In offshore wind power, subsea oil and gas development, and marine engineering, risers, umbilicals, and flexible pipelines are exposed to complex ocean currents for extended periods of time. As seawater flows around cylindrical structures, it generates periodic vortex shedding, a phenomenon known as vortex-induced vibration (VIV). If not effectively controlled, VIV can cause fatigue damage to pipes or cables, shortening their service life and even leading to structural failure.

To address this issue, VIV strakes (VIV suppression strakes) are widely used in engineering projects. By modifying the flow characteristics of the fluid, they reduce the energy of synchronous vortex shedding, thereby significantly attenuating structural vibration.

VIV suppression system design

VIV strakes typically feature a spiral or delta-wing design and are installed around the outer surface of a pipeline or riser. Their key features include:

Disrupting vortex shedding: Reduces vortex coherence by altering the incoming flow path.

Reducing lateral vibration: Effectively reduces the amplitude of the pipeline's lateral oscillation.

Corrosion-resistant, high-strength materials: Constructed from polyurethane and seawater-resistant metal, they ensure long-term performance in harsh marine environments.

Modular installation: Can be pre-installed or assembled in sections at sea, suitable for both new construction and in-service retrofits.

Application scenarios

Offshore wind farms: Used for VIV suppression on risers and umbilical cables, ensuring long-term, stable operation of cables and pipelines.

Deepwater oil and gas platforms: Used on risers, steel catenary risers (SCRs), flexible piping, and other locations to extend service life.

Marine engineering structures: Suitable for deepwater observation platforms, transmission pipelines, and other facilities requiring fatigue protection.

Advantages and value

Lightweight components: Reduce transportation and installation stress, saving time and money, and enabling efficient and rapid installation.

Adaptable: Customizable designs can be tailored to suit different pipe diameters, ambient flow rates, and service life requirements.

High-temperature resistance: Up to 100°C/212°F, UV-resistant, with a service life of at least 25 years, reducing maintenance and replacement costs.

Protection: Available with an anti-fouling coating or paint to prevent the accumulation of marine life.

For more information on customization and related details, please contact us via WhatsApp: 19941574798 or email: sale06@kfqizhongji.com.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.