Submarine cable protection pipes are key components ensuring the safe and stable operation of submarine cables. Their role is to resist risks such as erosion and mechanical damage to cables caused by the complex marine environment, guaranteeing the stable transmission of electricity from land or other platforms to offshore platforms.

Core Functions and Technical Principles

1. Physical Protection and Impact Resistance

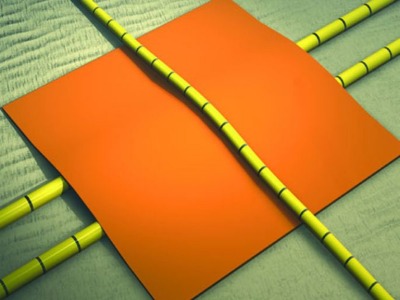

Compression and wear resistance: The surface hardness of the polyurethane protective sleeve reaches Shore A 80-95, capable of withstanding friction from seabed reefs, sand and gravel as well as ocean current scouring. Its dynamic compressive strength is 10MPa, adapting to deep-sea high pressure.

Cushioning structure design: Some protective sleeves are equipped with built-in elastic buffer layers, which absorb external impact through deformation to avoid damage to the cable insulation layer.

2. Corrosion Resistance and Long Service Life

Polyurethane materials resist seawater salt spray, microbial adhesion and chemical corrosion, with a service life of more than 20 years—significantly outperforming traditional metal protection tubes.

3. Dynamic Bending Control

The flexible design enables a bending radius of only 5-8 times the pipe diameter, preventing internal fractures caused by excessive cable bending. It is particularly suitable for dynamic areas with complex seabed terrain or platform connections.

Typical Application Scenarios

Landing section: The vertical or inclined section from the bottom of the platform jacket or pile legs to the seabed. This section is susceptible to falling objects, friction and bending stress.

Span section: The part of the submarine cable that crosses seabed gullies or obstacles without touching the seabed. It is prone to current scouring vibration and fishing gear dragging risks, and the protective sleeve enhances its fatigue resistance and impact resistance.

J-tube termination: The key transition point where the submarine cable enters the platform interior or passes through the J-tube. The bending stress here is extremely high, so a bending stiffener must be used.

Seabed section: In high-risk areas such as dense fishing grounds, anchorages and rocky seabeds, even if the submarine cable is buried, protective sleeves may need to be installed before burial or for exposed sections.

Summary

In the field of offshore platform power supply, submarine cables are crucial lifelines. Submarine cable protection pipes are by no means dispensable accessories, but key engineering measures to ensure the safe, reliable and long-term operation of this lifeline in harsh marine environments—especially in high-risk, high-stress areas around platforms.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.