Diverless J-tube seals (J-tube sealing system) can fix and seal submarine cables in offshore wind power, submarine communications, power transmission, and other projects, ensuring the long-term stable operation of the system. It is a safe, durable, and easy-to-install professional solution developed to meet this demand and is widely used in J-tube systems that introduce cables into submarine structures.

Structural features

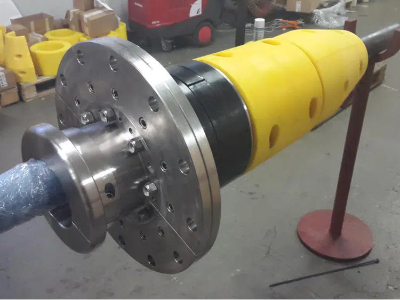

J-tube seals are composed of multiple high-performance components, with a compact design and comprehensive functions, including:

• Seal body: usually made of highly elastic polyurethane material, forming close contact with the cable outer sheath and the inner wall of the J-tube to achieve effective sealing.

• Metal structural parts: S316L stainless steel is used as the standard configuration, with excellent corrosion resistance. Super duplex stainless steel can be selected according to project needs to cope with more demanding environments.

• Connection flange system: easy to connect with accessories such as PCS elbows to ensure structural integration.

• Customized interface: can be customized according to the cable sheath material (such as PPY polypropylene) and project pressure and tightening requirements.

Core functions and effects

• Sealing effect: The seal effectively prevents seawater, silt and corrosive substances from entering the J-tube through high-strength bonding with the cable sheath and the inner wall of the J-tube, protecting the cable from long-term stable operation.

• Stable fixation: Fix the position of the cable at the bell mouth of the J-tube to prevent the cable from shifting due to water flow, tension or vibration.

• Adaptable anti-corrosion medium: When the J-tube is pre-filled with anti-corrosion inhibitors (such as protective liquids), the seal provides the necessary closed environment to prevent fluid leakage.

Installation advantages

The diving-free design is the biggest highlight of the J-tube seal, which significantly improves the installation efficiency and safety:

• Pre-installation on board: The assembly and pre-assembly of the seal can be completed on board before the laying of the submarine cable, without the need for divers to work underwater, greatly reducing the operation risk.

• Cost saving: Eliminate the use of divers and special underwater operation equipment, reducing the overall installation cost.

• Rapid deployment: The installation process is convenient and can be carried out simultaneously with the laying of the submarine cable to improve the project progress efficiency.

Compatible accessories

To improve system compatibility and functional expandability, J-tube seals can be used with the following supporting components:

• PCS elbow: to achieve a smooth transition between the submarine cable and the platform structure.

• Bend Restrictor: to prevent the cable from being damaged due to excessive bending and extend the service life of the system.

• Anti-pull-off clamp: to enhance the fixing strength of the cable at the J-tube mouth, suitable for deep water or high tension environment.

• Filling seal ring/module: to adapt to different cable sizes and achieve wider compatibility.

The diverless J-tube seal has become an important part of modern submarine cable laying projects with its reliable structural design, efficient sealing performance and convenient installation method. Customized services can also be provided for different cable structures and engineering requirements to ensure the long-term and stable operation of the sealing system in various complex marine environments. If you need to learn more about product specifications or obtain technical support, please contact us.

You can contact us any way that is convenient for you. We are available 24/7 via email. You can also use a quick contact form below or visit our website. We would be happy to answer your questions.